In a training center in Qatar, a connected video wall consisting of several screens was installed before the end of 2018. However, it became apparent that extreme reflections on the screens made it impossible to view the images and videos. With the help of Neoxum's reflection-reducing anti-glare screen protection, the video wall became anti-reflective and the installation was "saved". The video wall may remain on the wall.

In the direct neighborhood, the almost completed stadium for the FIFA 2022 World Cup in Qatar.

Differences in brightness between the environment and the screen

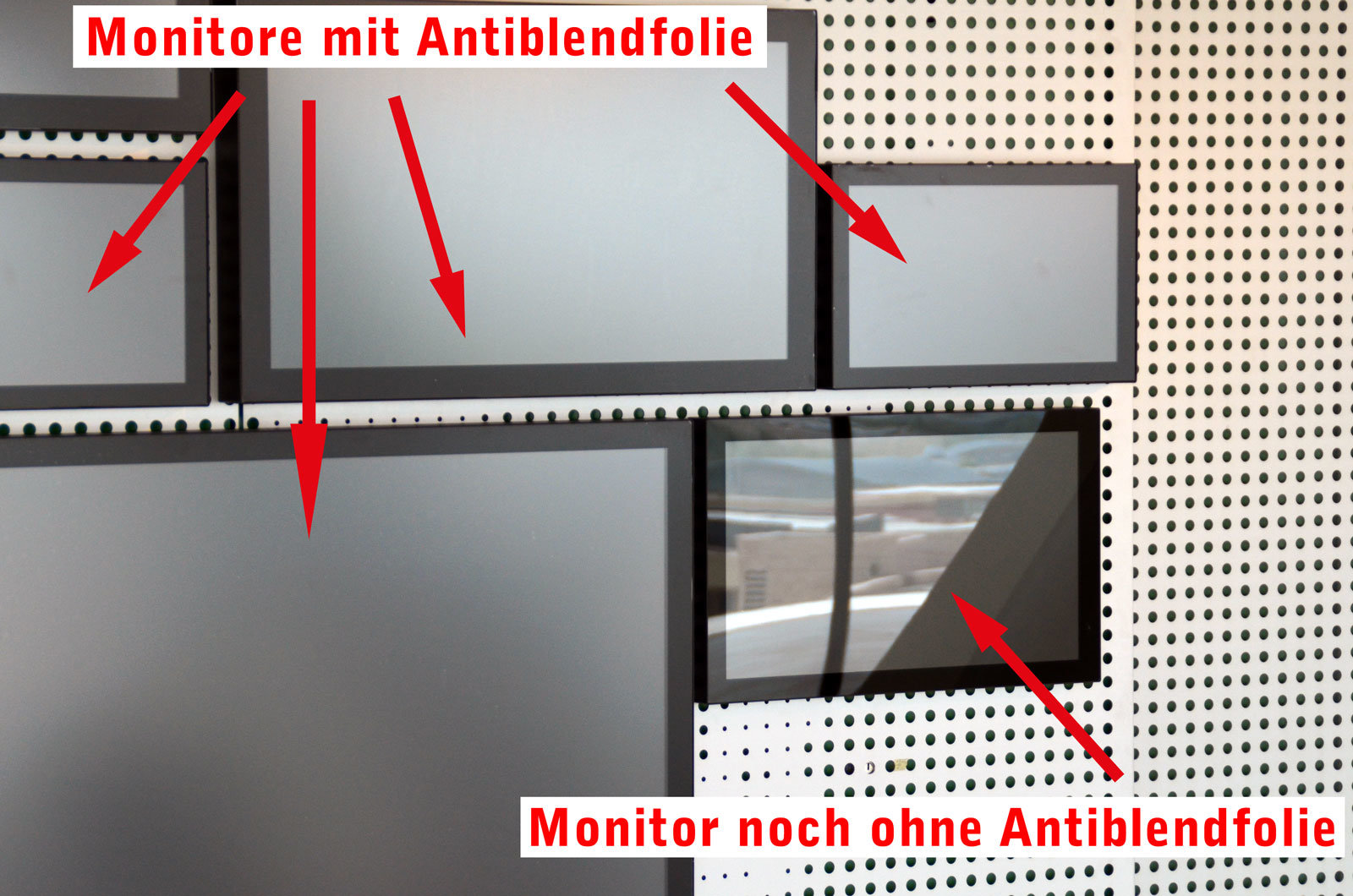

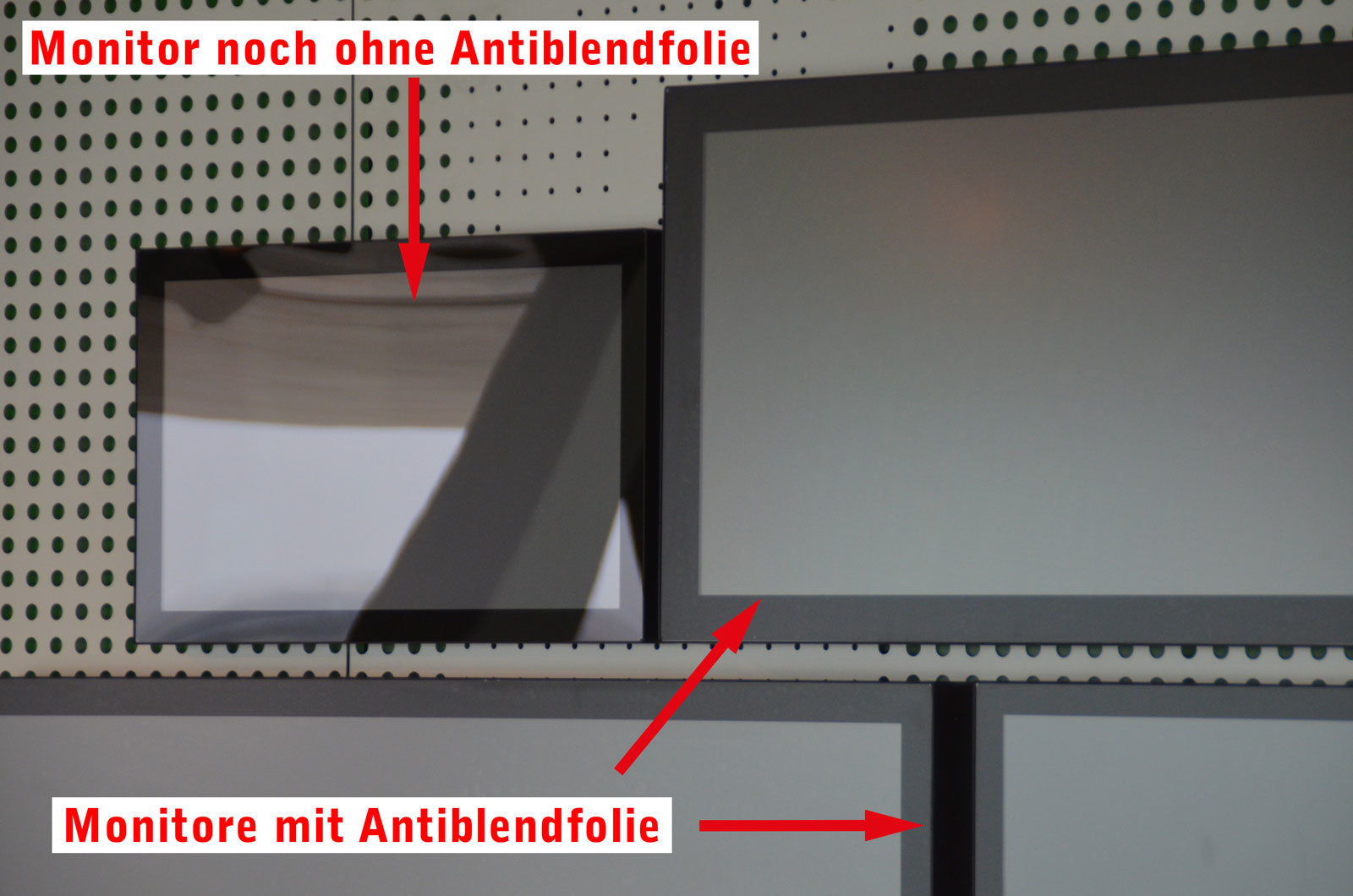

With a total of 11 screens ranging in size from 11 inches to 46 inches, the video wall was installed on a wall opposite to large windows flooded with light. After completion of the video wall, however, it became apparent that the brightness of the environment was almost double the brightness of the professional digital signage displays used (approx. equivalent to 800 lux) at approx. 1500 lux (1 lux corresponds to one lumen per square meter).

Reflections of the environment on the video screen

The reflections of the surroundings are so pronounced due to the bright environment with peak lights that visitors partly cannot see anything on the displays of the video screen. At the very least, viewing the highly reflective surfaces is very unpleasant and exhausting.

Project antireflection treatment video wall

After analysis and discussion with the customer and the shipment of sample materials, the solution with the Neoxum anti-glare film turned out to be very efficient. Thus, the only question that remained to be resolved was how to equip the displays already installed in Qatar with our anti-glare protective film. We were very positively surprised when the customer asked us directly for help: As the manufacturer of the protective film, we were also supposed to apply the films to the screens of the video wall in Qatar. Now you don't just go to Qatar for a few hours by car (as the crow flies Qatar - Munich: 4300 km). After clarifying the questions about the outbound and return flights, the following topics were agreed upon:

- Material transport from Schöngeising to Qatar

- Tools such as cleaning fluids for cleaning the monitors before mounting the film. The airlines' regulations on the transport of liquids had to be meticulously followed.

- Accommodation and transportation

- Time schedule and personnel resources: larger displays from approx. 24 inches upwards can be equipped with an anti-reflective film in a much more relaxed manner with 2 people

- Organization of the on-site facilities: the ambient air of the room with the video screen is quite dusty due to visitors

- Discussion of the customer's requirements regarding size and contour of the anti-glare films to be produced, as well as possible dust inclusions during assembly (no clean room was available)

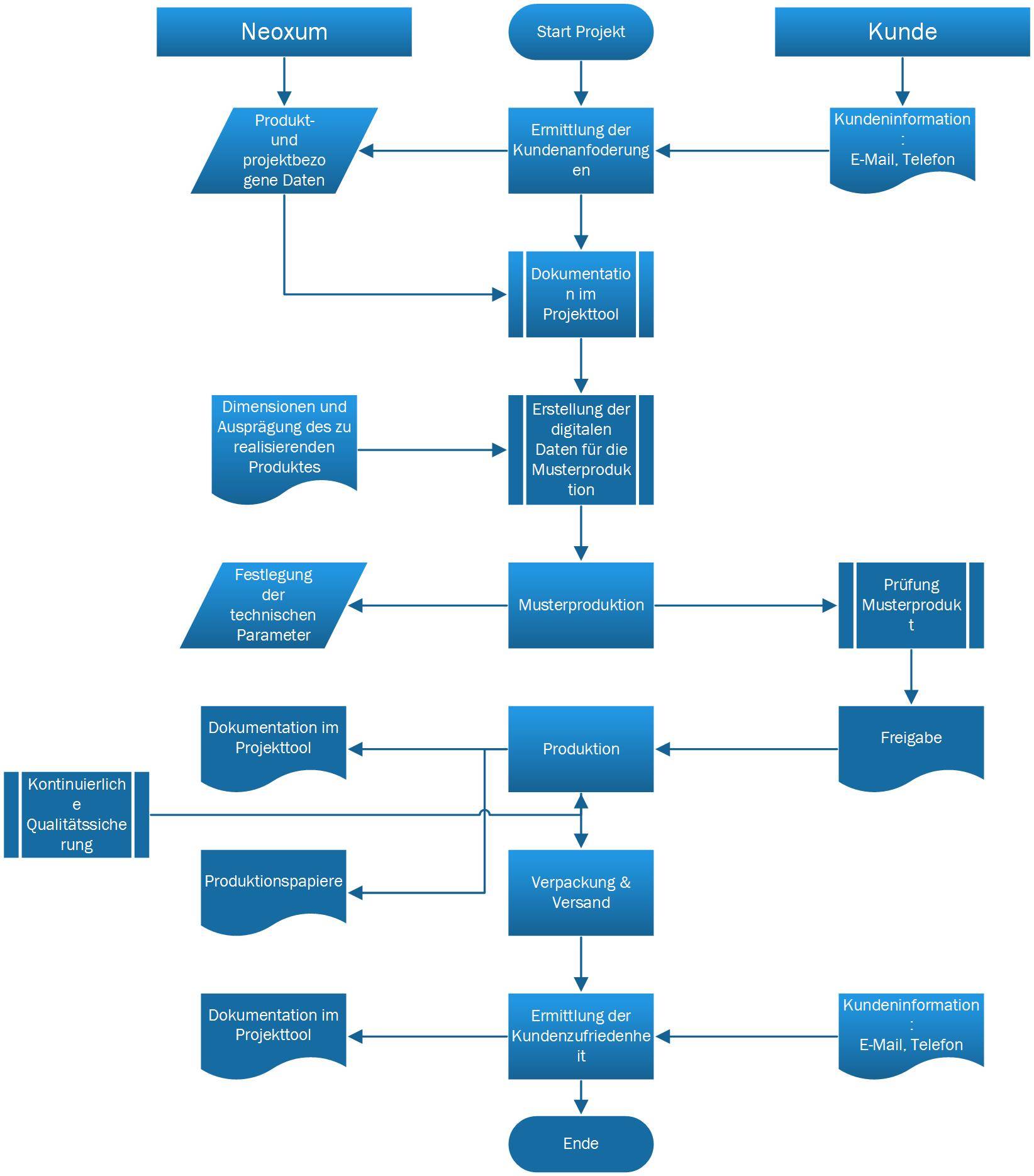

Our generally applicable project workflow is shown below as an example within the context of our ISO 9001 quality certification. If you have any questions about projects concerning display protection, anti-reflective coating of large-sized screens or protection against mechanical damage to surfaces of displays and monitors, please contact us.

Assembly of the anti-glare layer

After all open questions had been clarified, perfectly tailored anti-glare films were sent on their way to Qatar by air freight. In addition, there was a whole smorgasbord of necessary equipment:

2 rolls of household wipes

2 microfiber cleaning cloths

1 roll of adhesive tape

1 cutter knife

1 scalpel

1 pair of tweezers

1 measuring tape

1 antistatic feather duster

1 squeegee large

1 squeegee small

1 felt squeegee

1 canister of distilled water, approx. 3 liters

1 pump spray bottle, large, empty

1 pair of scissors

250 ml of antistatic cleaning fluid (registered in advance with the authorities and the airline via data sheet)

The installation of the anti-glare films in Qatar proved to be a challenge, as there was no room available with the low dust load that was actually required. We solved the problem by applying the Neoxum films to the individual monitors using a floating technique. This means that the statically adhering silicone adhesive layer of the protective film is wetted with distilled water and only then the film is applied to the display in a floating manner. Due to the water film, protective films in large format can be briefly lifted again in the case of immediately visible dust inclusions and the troublemaker may be removed. In addition, the thin liquid film facilitated the exact positioning of the large film. The thin liquid film of distilled water evaporates completely and without residue (only aqua dest!). We would like to point out urgently at this point that an assembly according to this method is to be carried out only at powerless devices. Complete drying and evaporation must be allowed to take place. For a 46 inch screen, drying takes approx. 24-48 hours with proper installation at room temperature.

Results applying anti-glare screen protectors onto videowall in Qatar

Within two days, the complete video wall was equipped with Neoxum anti-reflection protective films by us on site. Besides the significant reduction of reflections (we took some photos during the work), another very positive side effect showed up.

On site, the customer (and we did so) made us aware that some display already have some small damages, such as scratches or small blind spots. After applying our professional screen protector, these spots were no longer visible! The anti-reflective layer of the Neoxum display film actually makes small damages and scratches "disappear". The customer was highly satisfied with the work and result: finally, the innovative Videowall can be viewed without annoying reflections and without effort. Visitors to the videowall installation will be grateful!

. A strong 256-bit encryption secures the data transfer. With our externally issued SSL certificate, we are transparent and compliant. In addition to the SSL-secured website, we take data protection very seriously.

. A strong 256-bit encryption secures the data transfer. With our externally issued SSL certificate, we are transparent and compliant. In addition to the SSL-secured website, we take data protection very seriously.

Latest comments