Display protection - a comprehensive explanation and overview

What you need to know about screen protectors

What is a display film and why is it beneficial?

Display protection foils are specially manufactured films that are supposed to protect the touchscreen as a protective layer from the factory now and then. They can also be manufactured and applied afterwards in a suitable form using various manufacturing processes. The task of a display protection film, also known as a display film, touch film, touch screen film or touch protection film (no generally valid name has been established to date) is the efficient protection of the device display against display damage, such as scratches and scuffs, and even the prevention of display breakage. In addition, display films protect against chemicals, such as cleaning agents or disinfectants, dirt and grease.

Protective effect of a professional screen protector

The display of the cell phone is one of the elements that are most battered. Especially in case of drops or bumps, the screen is rapidly damaged or scratched and the function is consequently hindered or even completely impossible. A display film exerts a protective effect to protect the screen from external influences, such as scratches in particular. It thus ensures that the cell phone remains usable for a long time. Coins, keys or other hard pointed objects, such as sand, zippers can scratch a smartphone monitor. If the phone falls on the street, the screen can even crack. This is not only annoying, but a display repair can be downright salty at times. Everyone knows the cell phone spider app! Additional protection with a Neoxum anti-reflective film or Neoxum ultra-clear film is therefore highly recommended.

A broken screen, for example, makes a cell phone or digital camera completely unsuitable. An expensive repair is certainly the consequence, if not a new acquisition is sometimes the economically more sensible solution to the problem. Without question, this is incredibly annoying and expensive, and in the case of a total loss, it is also not particularly ecologically beneficial, as

- the old device accumulates as electronic scrap

- the disposal of electrical equipment, which is still not reliably solved.

Better and significantly cheaper is the preventive protection of expensive utensils with professional display protection from Neoxum.Principally, there are two essentially different types of display protection. Flexible display protection, which protects touchscreens from scratches and damage and rigid diplay protection made of pure glass.

Higher sales value for used equipment

When signing a smartphone contract with a common term of 2 to 4 years, a brand-new cell phone is usually included. When the existing contract is extended, the customer often receives a brand-new smartphone. The former phone is no longer needed and is sold. Defects, especially on the screen, reduce the resale value. With the help of high-quality display protection from Neoxum, as a display protection film, anti-reflective OnScreen Hybridglas or crystal-clear OnScreen hybrid glass, the display or display glass remains unharmed and a higher sales value is achieved.

Quality display protection

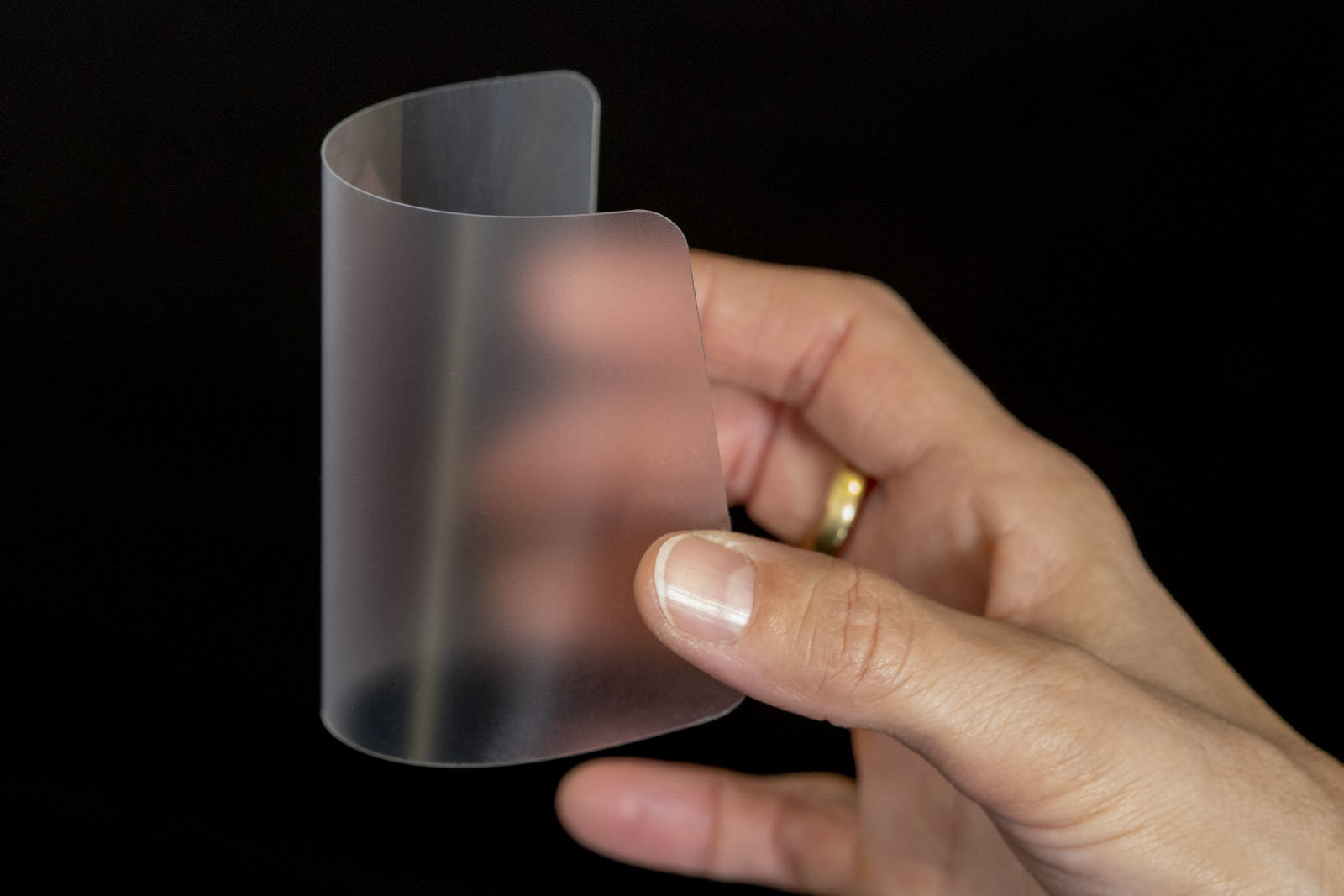

Surface hardness, material thickness, transparency and also the sensitivity change of the sensor screen are decisive for the quality of a display protection film. The harder the screen protector, the more resistant it is against scratches. Usually, the hardness of the screen protector's surface is indicated in pencil hardness H. But the elasticity also plays an important role: We know this phenomenon from nature. Trees sway in a storm and yield to the force of the wind. Even in powerful storms, healthy trees generally withstand the forces of nature by yielding to the force elastically and adaptably.

Bamboo and protection of displays - an analogy

plastic prime example are the Asian breathtaking scaffolds made of bamboo. The natural material (bamboo is a grass!) is enormously flexible and elastic, yet very strong. Bamboo scaffolds are used to build entire skyscrapers. Rigid steel scaffolds, on the other hand, can withstand occurring forces only to a certain extent, until they undoubtedly break. Only the movable scaffolds made of bamboo are so resistant that they can withstand the enormous loads. Responsible for this extraordinary peculiarity is the modulus of elasticity.

And how does this all relate to screen protectors?

Rigid glass screen protectors (tempered glass) certainly have an outstandingly hard surface to protect the screen against scratches and scuffs. Currently very popular is the so-called bulletproof glass (bulletproof glass, real glass or tempered glass protection, tempered glass). This item is real glass. As pure protective glass, bulletproof glass is also often referred to as shockproof display protection glass or anti-shock protection glass. Sometimes it is advisable to question this advertised shock-absorbing feature. In case of an abrupt force (an impulse), for example a fall or a pointed object with a punctual load, a blow or impact with a screwdriver or the like (the device falls with the display on a hard floor), screen protectors made of pure glass break quite quickly. Unfortunately, small pointed and sharp-edged splinters often occur, which pose a not inconsiderable risk of injury.

Display protection for industrial quality requirements

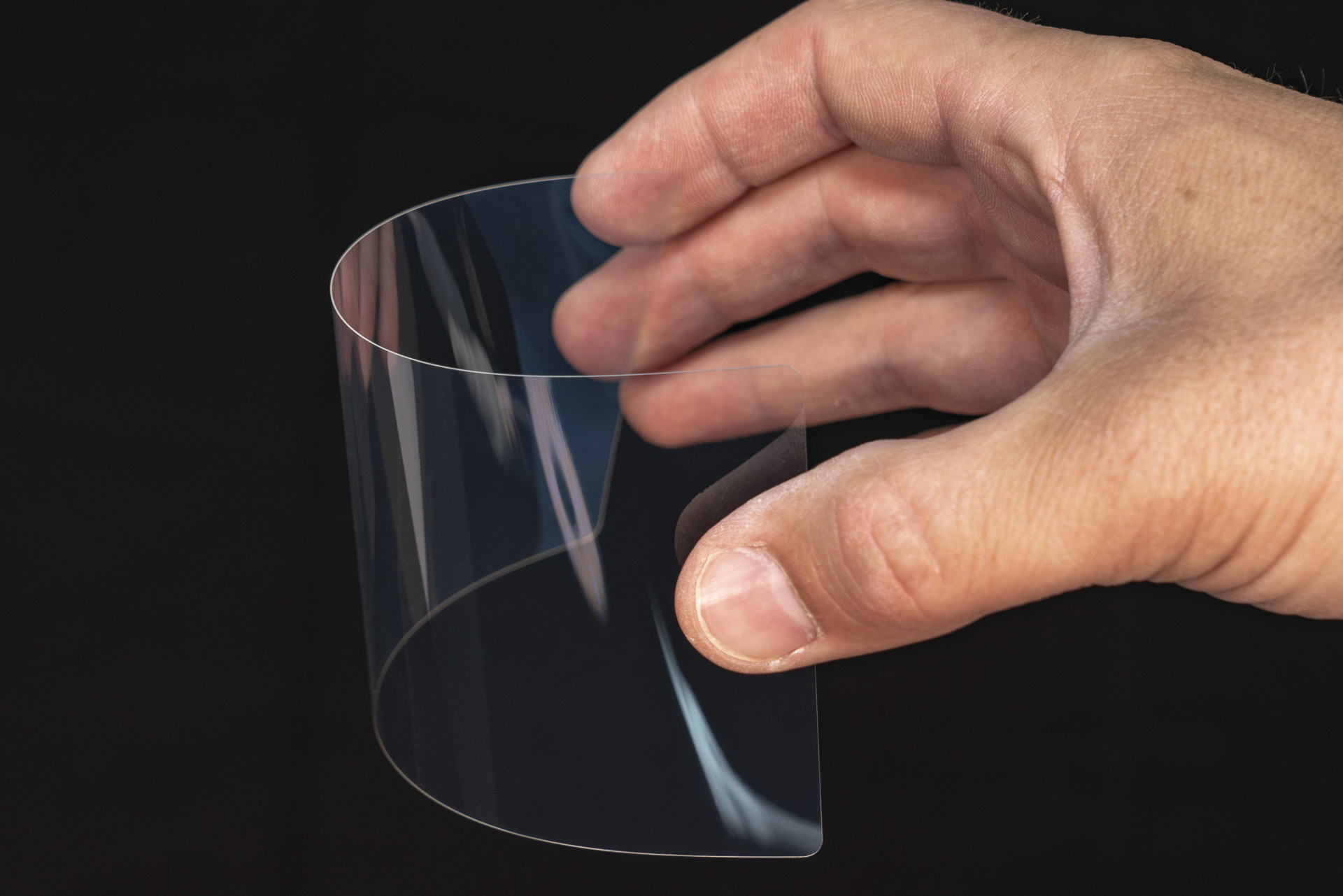

Particularly in the field of industrial display protection, bulletproof glass, also known as armored glass, flexo glass, or protective glass, has not prevailed because occupational safety plays an extremely important role here. Neoxum offers the solution with OnScreen OnScreen Hybrid Glas: the hybrid material has a surface as hard as glass up to 9H and is still flexible like a display film. The combination of glass with an intermediate layer of protective film does not break and behaves more like safety glass or laminated glass.Obviously, the protective films for touchscreens available on the market differ in their quality. An inferior film does not withstand sharp-edged objects.

For example, display protection films, bulletproof glass and hybrid glass are currently being used successfully in the following commercial segments:

- Clinics, hospitals, nursing homes and colleges that need to anti-reflect and incidentally protect and disinfect displays of medical and veterinary examination equipment and patient displays

- Public transport companies that use display protection films, respectively glass hard display protection on conductor devices, ticket machines, ticket vending machines and information terminals to protect them from wear and tear and destruction

- Agricultural machines such as combine harvesters, tractors, milk milking machines, which are now operated with touch functionality on control panels

- Touch panels on CNC milling machines, lasers, NC controlled punching machines

Haftwirkung Displayschutz mittels Adhäsion

Adhäsionskraft auf glatten Oberflächen

Hochwertiger Displayschutz im allgemeinen und Displayschutz aus Glas, wie z.B. OnScreen Hybridglas haftet rein mit Hilfe von Adhäsionskraft auf der Displayoberfläche. Mithilfe von Kräften im Nanometerbereich, ohne die Anwendung von Klebstoffen, wird eine außerordentlich starke Haftwirkung erzielt, die ein Rutschen oder Abfallen vollständig verhindern. Gleichwohl lassen sich Adhäsionsfolien und auch OnScreen Hybridglas sehr einfach von einem Display rückstandsfrei wieder abnehmen. Man muss in diesem Fall den Displayschutz nur an einer Ecke mit einem Fingernagel hochziehen und dann schräg nach hinten abnehmen. Die Relation von Haftkraft und den benötigten Kräften zum Entfernen kann man sich praktisch wie folgt vorstellen. Legt man zwei plane Glasplatten unmittelbar aufeinander, wird der Luftspalt zwischen diesen beiden in Gänze verdrängt. Der umgebende Luftdruck drückt die Platten enorm kräftig aneinander. Will man die beiden trennen, gelingt das mit Menschlichen Kräften nicht. Wendet man einen Kniff an und schiebt die Platten auseinander, gelingt die Aufspaltung jedoch sehr leicht.

Physical Chemical Forces

Several factors play an important role in the adhesion of high-quality screen protectors to screen surfaces. Adhesion is a decisive phenomenon in the molecular range that arises from polar interactions at interfaces, in our case the interface between the display surface and the silicone adhesive layer of the display protector. In particular, so-called van der Waals bonds in the area of molecules of the display surface and molecules of the adhesion layer (the very thin silicone adhesive layer) are decisively responsible for the strong adhesion to smooth surfaces. The decisive condition of adhesion is the spatial proximity of the two surfaces. The silicone adhesion layer of the Neoxum display protection or surface protection is such that Neoxum display films, as well as the OnScreen Hybrid Glass adhere extremely well to numerous smooth materials, such as plastic, metal, but also glass. The adhesive film and the hybrid glass can be removed from all materials without leaving any residue.

Aufbau einer Displayfolie

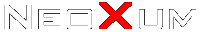

Display protection films consist of different layers that are specially adapted for their purpose. A silicone adhesive layer allows the films to stick to the screen surface. A simple and bubble-free installation is indispensable. The essential protective layer, made of PET high-performance film, pure glass (= very brittle, risk of breakage) or a hybrid material consisting of a glass-hard surface and elastic special polymer (=OnScreen ® Hybridglas), ensures that the monitor is protected from damage. The operation of the touch display is not restricted by the additional high-performance protective layer. Displays made of tempered glass (often referred to as Gorilla Glass, bulletproof glass or armored glass) are also not insensitive to scratches or other signs of use when they are hit with very hard objects. The following is a short excursion into the assessment of surface hardness degrees.

Transparenter durchsichtiger und anti-reflektierender Displayschutz

Transparenter Displayschutz

In komplett glasklarer Ausführung ist der Displayschutz so gut wie nicht mehr zu erkennen. Der klare Displayschutz schützt das Display wie eine zweite Haut. Farben werden naturgetreu wiedergegeben. Der transparente Schutz des Displays wird bei hochwertigen Erzeugnissen nicht mehr wahrgenommen. Zumeist erkennt das ungeübte Auge überhaupt nicht, dass sich eine transparente Displayschutzfolie auf der Anzeige befindet. Die Eigenschaft des Touchscreens beeinflusst die Folie aber in keiner Weise. Die berührungsempfindliche Touchfunktion funktioniert auch mit der aufgebrachten Dislayschutzfolie gleichermaßen, wie es soll. Neoxum ultra klare Displayschutzfolien sind mit einer abweisenden Anti-Fingerprint Schicht beschichtet, die unschöne Fingerabdrücke merklich reduziert.

Entspiegelnder Displayschutz

Als Anti-Reflex Displayschutz werden Spiegelungen auf der Displayoberfläche effizient reduziert: Der Bildschirm wird entspiegelt und nebenher durch die extra Schutzschicht vor Beschädigung geschützt. Die entspiegelnde Oberfläche gewährleistet in hellen Umgebungen, gerade bei der Arbeit im Freien, hervorragende Dienste. Das Display lässt sich viel besser ablesen. Keine ärgerlichen und behindernden Spiegelungen mehr.

Wie hart ist Displayschutz tatsächlich?

Die Einteilung, wie hart ein Displayschutz ist, wird in der Welt des Oberfläche und Displayschutzes in Mohs’schen Oberflächenhärtegraden gemessen. Folgende Tabelle listet die verschiedenen Härten der Oberflächen des Displayschutzes auf und vergleicht diese mit einem natürlich vorkommenden Werkstoff und einem Alltagsgegenstand:

Härtegrade von Materialien

| Härtegrad H | so hart wie | Beschreibung Härtegrad |

|---|---|---|

| 1H | Talk Mg3[(OH)2/Si4O10] | Material lässt sich einfach mit Fingernagel eindrücken, Folie aus Poylpropylen oder Polyethylen |

| 2H | Gips CaSO4*2H2O | Material lässt sich gerade noch mit Fingernagel eindrücken |

| 3H | Kalkspat CaCO3 (Calcit) | hochwertige Display Schutzfolie aus PET (Polyethylenterephtalat) |

| 4H | Flussspat CaF2 | hochwertige Displayfolie aus PET (Polyethylenterephtahlat) |

| 5H | Apatit Ca5[(F,Cl,OH)/(PO4)2] | einfaches Fensterglas |

| 6H | Feldspat KAlSi3O8 | Material lässt sich mit einfachem Küchenmesser einritzen |

| 7H | Quarz SiO2 | so art wie gehärtetes Glas, Gorilla Glass, Panzerglas oder OnScreen Hybridglas von Neoxum |

| 8H | Topas Al2[F2/SiO4] | |

| 9H | Korund Al2O3 | so hart wie Saphirglas, z.B: Uhrglas für hochwertige Uhren; Schmuck |

| 10H | Diamant C (Kohlenstoffmodifikation) | härtestes weithin bekanntes Material, Diamant kann nur mit Diamant geschliffen oder geschnitten werden |

Wie aus obiger Tabelle ersichtlich, muss man Aussagen, wie Diplayschutz hat 9H, mit Vorsicht genießen. Korund bzw. Saphir (ein mit Chrom (III) dotiertes Al2O3 (Aluminiumoxid); wird auch als Rubin bezeichnet und ist rosa bis rot eingefärbt) sind enorm teuer und als sehr dünne Schicht nur mit speziellen außerordentlich kostspieligen Verfahren, z.B: PVD (physical vapor deposition) oder CVD (chemical vapor deposition) aufzubringen. Ein Schutzglas mit 9H Härte für 5,99 EUR kann dementsprechend kaum der Wahrheit gleichkommen! Seriöse Lieferanten und Hersteller nennen 7H als Härte (siehe obere Tabelle) für Displayschutz aus Glas, bzw. glasharten Displayschutz.

Curved displays - 2D - 2.5D - 3D protective glass

In addition to the distinction between transparent and anti-reflective display films and protective layers made of glass or a glass-plastic composite (OnScreen Hybrid Glass), there are other differences that can be indicated with D-data: 2D films only cover the monitor, 2.5D films also protect the screen edges in strongly curved displays, and 3D films reach beyond the screen.

Protective films applied by the device manufacturer

Factory-installed protective films are usually made of polypropylene (PP) or PE (polyethylene) or PVC (polyvinyl chloride) and act more as a transport protection film than a real display protector. These transport protection films, most of which are not cut to fit exactly, are supposed to protect the screen from display damage during final assembly and packing. After this functionality is fulfilled, the particularly easy-to-adhere protective film can simply be removed from the display after the device is purchased. However, there are now exceptions where primarily cell phone manufacturers pre-mount good protective films on the monitors.

Inexpensive display film set

Display films are small useful helpers against the damage of screens and sensitive surfaces. The protection of the display or screen in inexpensive display films is usually made of PE (polyethylene), PP (polypropylene) or PVC (polyvinyl chloride). Adhesion to surfaces is usually achieved by using adhesives (acrylates or modified acrylate adhesives), which are applied in very thin layers (usually less than 10-20 g of adhesive per square meter of film). Alternatively, for somewhat better protection of displays made of the above-mentioned materials, an adhesive silicone layer is used as an adhesive (adherent but not adhesive) layer.

Cheap protective films

What all three inexpensive to very inexpensive display films have in common is the fact that they are comparatively thin. As a rule, the thickness of inexpensive display films is no more than 60 microns, which corresponds to 0.06 mm. In addition, protective films made of PE and PP are very soft and flexible. This means that the sensitive polymer can be deformed very easily with a small amount of force (better: pressure = force per area). If the applied force (e.g. a zipper scratches the thin protective film) exceeds a certain maximum value, which is very low for simple protective films, an object (key, pen, coin, ballpoint pen, rivet on jeans, stone, zipper, etc.) breaks through the thin polymer protective layer in an instant. The display underneath will certainly be damaged. On top of that, inexpensive protective films defy horizontal shear forces marginally: they can be stretched out extremely effortlessly. When stretched, film material thins out until it tears off when the stretching capacity is exceeded. The low durability and resilience is the reason why cheap suppliers usually offer packs of 3, 6, 9 or even 12 for little money. The protective films are broken relatively quickly and must then be replaced.

Plain display protectors are mostly die-cut in Asia in multiple layers using contour cutting dies. This can sometimes lead to bruising at the cut edges. This not only affects the fit, but also the adhesive layer. In the worst case, the inexpensive screen protector film does not adhere to the edges of the touch display and sticks out. This kind of screen protector does not meet industrial quality standards. According to our advice, displays should be equipped with high-quality and professional screen protectors.

Insufficient surface hardness of cheap display protection films

The low surface hardness of cheap films also very quickly leads to the surface of the inexpensive display film itself becoming noticeably scratched and you can hardly see anything on the display.

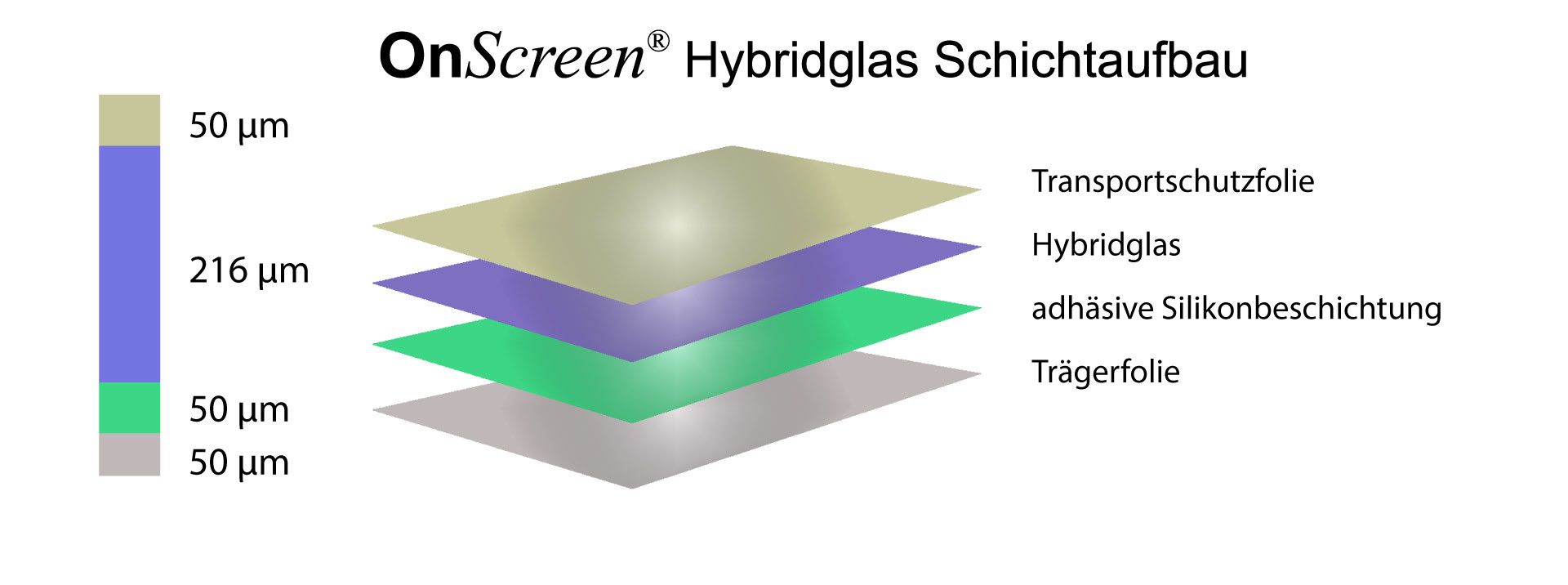

Professional Screen and Surface Protection

Professional display protection films are usually made of PET (polyethylene terephthalate) a polyester material. PET has outstanding optical properties, high tensile strength, a Young's modulus 4500 N-mm2 longitudinally and transversely, i.e. with a thickness of the material qualified for a professional screen protector of about 0.1-0.13 mm, an extremely powerful and hard protection of the display is given. Sharp pointed objects cannot easily penetrate to the device display. The screen under the screen protector is protected with high efficiency. Protective films made of high-quality PET are highly resistant to chemicals. Furthermore, display protection films made of PET material are very temperature resistant. We have summarized the key features of Neoxum display films in our technical data sheet. Professional display films from Neoxum are used, for example, in the food industry or in the medical sector, where the displays must be regularly cleaned of germs with disinfectant. The disinfection of the screens does not harm the touch displays at all due to the protection provided by the display film or the OnScreen Hybrid Glass. The surface of good display films has a surface hardness of 3H - 4H. Scratches on the protective film cannot be avoided under massive and intensive load in industrial or commercial use. However, a professional screen protector from Neoxum protects touch displays and displays from scratches, damage, chemicals, including cleaning agents without negatively changing the touch properties.

Why is a good screen protector fit essential?

High-quality display films and OnScreen hybrid glass from Neoxum are produced in Germany on modern precision laser machines. The small recesses and cutouts on the device display are different sensors of the device. On a smartphone, for example, there are light sensors, proximity sensors, in some cases several camera lenses on modern smartphones, microphone, speaker outputs and several more cutouts. In order not to prevent the function even with a screen protector, all cutouts for the detectors of the device are taken into account. This is especially relevant for light and proximity sensors. The light-sensitive sensors are used to regulate the automatic shutdown of the display during a phone call and the automatic brightness of the display. For Neoxum display films as well as OnScreen Hybrid Glass, the dimensions are always taken from the original device. As already explained, all cut-outs are important for the dimensions. But also the dimensions have to be measured precisely digitally. There are manufacturers who use dummy devices (without electronics, only device housing and display) for measuring. Nevertheless, there can be significant differences to the real display. For curved displays, Neoxum display protection products are laser-cut so that neither the Neoxum protective film nor the Neoxum OnScreen Hybrid Glass protrude beyond the edges. Basically, hybrid glass adheres even stronger to the screen surface and is therefore very well suited for curved displays. An adhesive layer made of very thin silicone is responsible for the adhesive effect on the monitor surface. The adhesive effect is based on the physical principle of adhesion. We have already explained the adhesive effect based on forces in the nanometer range in more detail in another article.

Umweltbilanz Schutz von Displays

Vermeidung von Elektronikschrott durch hochwertigen Displayschutz

Erwartungsgemäß sorgt ein hochwertiger Displayschutz für ein verlängertes Geräteleben, weil die Schalteinheit, das Display, gut geschützt ist. Gebrochene oder kaputte Gerätebildschirme führen unweigerlich zu teuren Instandsetzungen oder gar einem kompletten Ersatz des Geräts. Oft lohnt es sich nicht, für viel Geld das Display zu reparieren, weil Neugeräte fast genauso viel kosten. Demzufolge sind gebrochene Displays oder Bildschirme, die auf Grund von Gebrauchsspuren oder einem Displaydefekt untauglich geworden sind, ökologisch extrem ungut. Vorsorglicher Displayschutz reduziert das Risiko eines Displayschadens auf Grund einer massiven Einwirkung, z.B. durch einen Bruch des Displays. Kratzer und Beschädigungen des Monitors werden vermieden und bei einem Sturz ist die Wahrscheinlichkeit entscheidend größer, dass ein mit einem Displayschutz ausgestattetes Display bei einem Zusammenprall mit dem Boden unbeschadet bleibt. Die Umweltbilanz ist mit Displayschutz also besser als ohne.

Kunststoffrecycling von Displayfolien

Displayfolien andererseits sind aus Kunststoff. Kostengünstige Displayfolien aus PP, PE oder PVC sind nicht besonders widerstandsfähig und müssen deshalb turnusmäßig ausgetauscht werden. Dies verursacht zum wiederholten Mal vermeidbaren Müll aus Plastik. PP und PE können wiederverwertet werden. Auch eine thermische Verwertung ist möglich, wobei nur Wasser und Kohlendioxid über bleiben. Trotzdem fabrizieren wir alle viel zu viel (Billig-) Plastikmüll. Besser sind hochwertige Displayfolien aus PET, die sehr robust und strapazierfähig sind. Zudem können PET Displayfolien sortenrein gesammelt werden und zum Beispiel zu Getränkeflaschen recycelt werden. Am schlechtesten schneiden PCV Displayfolien ab. PVC beinhaltet Chlorid (PVC=Polyvinylchlorid), das bei einer thermischen Verwertung (Müllverbrennung) zu giftigen Dioxinen, Furanen und Salzsäure reagiert. Mithilfe aufwendiger Prozessen müssen deshalb PVC belastete Abgase entgiftet werden. Auf lange Sicht sinnvoller ist es, auf billige PVC Folien zu verzichten.

Displayschutz auf das Display aufbringen

Staubarme Umgebung

Die wichtigste Regel bei der Installation von Displayfolien oder Displaysschutz aus Glas ist, sich etwas Zeit zu nehmen und eine staubarme Umgebung einzurichten. Eine entsprechende Umgebung schafft man sich selbst sehr leicht zu Hause im Bad. Hier ist die Luft nach dem Duschen oder Baden tendenziell feucht und darüber hinaus befindet sich in der Regel wenig Staub in der Luft. Optimale Konditionen für die Montage von Displayschutz (ausgenommen professionelle Montage mit Reinraumbedingungen).

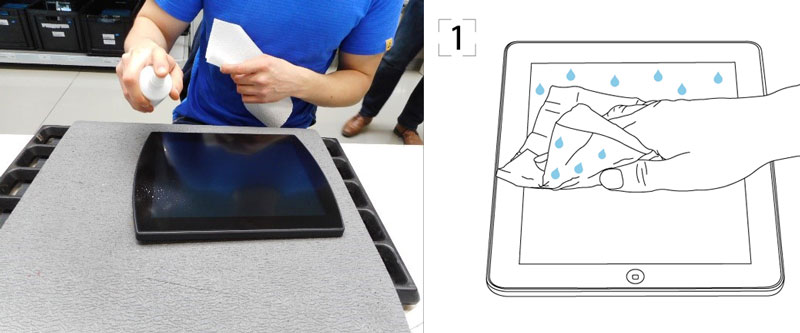

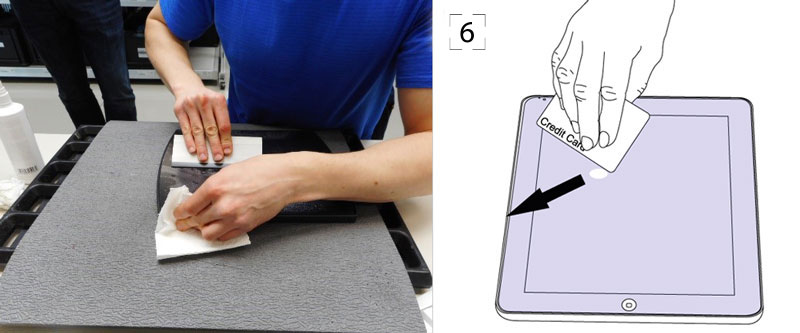

Reinigung des Touchscreens

Wie eine Schutzfolie oder auch Panzerglas, Hybridglas oder eine Glasfolie richtig auf das jeweilige Gerätedisplay aufgebracht wird, sollte bei hochwertigem Displayschutz in einer detaillierten Bedienungsanleitung erklärt sein. Die wichtigste Voraussetzung dabei ist, dass der Bildschirm fettfrei und frei von Staub ist. Im Normalfall findet sich bei Markenprodukten auch ein Reinigungstuch mit als Beigabe. Neoxum liefert zu diesem Zweck ein mit Bildschirmreinigerflüssigkeit getränktes Tuch für die Displayreinigung und ein Trockentuch zur Nachbearbeitung, sowohl für Neoxum Displayfolien, als auch OnScreen Hybridgläser, mit aus. Ein Mikrofasertuch alleine ist für die Entfernung von Fingerabdrücken oder Fett nicht so gut geeignet. Nur mit einem Mikrofasertuch ausgestattet, verschmiert man vielmehr Fingerabdrücke auf dem Display. In diesem Fall sollte man eine geeignete Bildschirmreiniger Flüssigkeit mit verwenden.

Zusätzlich ist es angebracht, mit dem beiliegenden Reinigungszubehör das Display von Staub zu säubern. Billige Mikrofasertücher laden sich, respektive der Bildschirm, statisch auf und somit zieht das Display noch mehr Staubpartikel an. In so einem Fall sollte man einen antistatischen Bildschirmreiniger obendrein benutzen, um Staubpartikel zu entfernen.

Einzelne Schritte der Displayschutzmontage

Passt der Displayschutz?

Zunächst legt man das Displayschutzprodukt, egal ob transparent oder anti-reflektierend auf das zu schützende Display um die Maßhaltigkeit zu prüfen. Passen alle Aussparungen? Sind Aussparungen für Kamera, Mikro, Lautsprecher etc. vorhanden? Passt Länge und Breite? Die Trägerfolie darf dabei noch nicht abgezogen werden!

WICHTIG: Gewöhnlich wird der Displayschutz ein klein wenig kleiner als die Dimensionen Displayrand zu Displayrand zugeschnitten, um das Aufbringen zu erleichtern. Der Displayschutz sollte rundherum ca. 0,1-0,2 mm kleiner ausfallen, als das Display selbst.

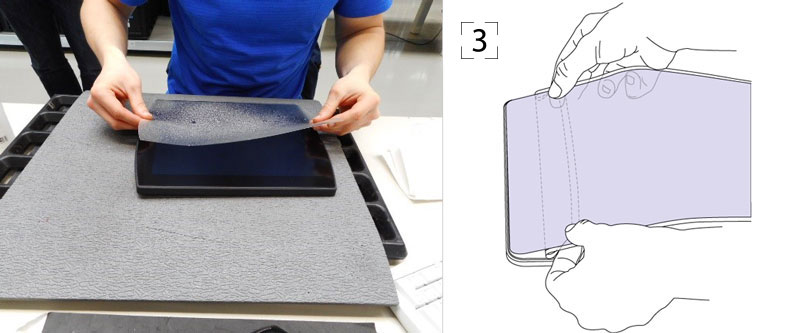

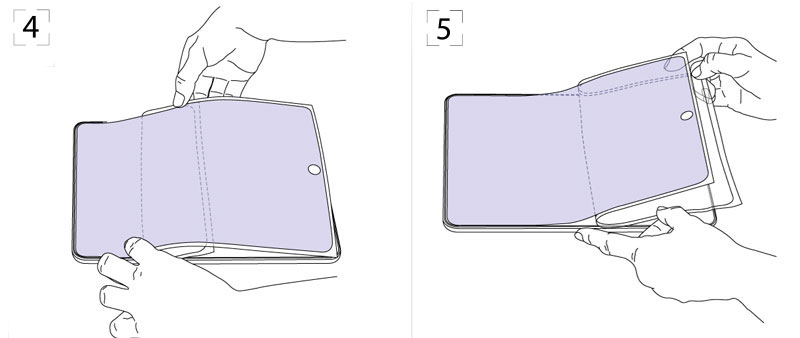

Partielles Abziehen der Trägerfolie

Im nächsten Schritt folgt ein partielles (ca. 2-4 cm) Abziehen des Displaschutzes von der Trägerfolie. Unterschiedliche Hersteller haben hier mehr oder weniger unproblematische Methoden entwickelt, um das Abziehen des eigentlichen Displayschutzes von der Trägerfolie zu erleichtern. Jedweder Neoxum Produkte, Displayschutzfolien, als auch OnScreen Hybridglas, werden im sogenannten Kiss-Cut Verfahren hergestellt. Dabei werden sämtliche Ausschnitte mit gelasert. Der Aussenumriss wird aber nur so tief gelasert, dass der Laserstrahl das Displayschutzmaterial nur sauber durchtrennt, ohne die darunter liegende Trägerfolie ebenfalls zu durchtrennen. Der Displayschutz lässt sich dann sehr einfach wie ein Etikett abnehmen. Es ist dabei zu achten, die nun freiliegende Silikonhaftschicht so wenig wie möglich mit den Fingern zu berühren.

Aufbringen des Displayschutzes

Die silikonversehene Haftseite des Displayschutzes wird nun auf die gereinigte, staub- und fettfreie Displayoberfläche in einem Winkel von über den Daumen gepeilt 30-45° an einer Kante angelegt und mit Bedacht Stück für Stück die Haftschicht auf den Touchscreen appliziert. Bei einem Displayschutz größer als 15 Zoll Diagonale empfiehlt es sich, an einer langen Kante anzulegen. Gleichzeitig zieht man nach und nach die Trägerfolie ab. Auf diese Weise wird die Displayfolie, bzw. Displayschutz, der aus Glas besteht, auf die Oberfläche aufgebracht, ohne dass dabei Lufteinschlüsse entstehen. Lufteinschlüsse können mit dem Daumennagel oder einer Plastikkarte, wie z.B. EC-Karte, zum Rand hin ausgestrichen werden.

Sollte trotz aller Vorsicht ein Staubpartikel zwischen Bildschirmoberfläche und Displayschutz gekommen sein, kann man das Staubpartikel mit einem Trick sehr einfach entfernen: Dazu schneidet man ein ca 5-7 cm langes Klebeband (z.B. von TESA oder SCOTCH) ab und klebt es an der dem Staubkorn am nächsten liegenden Kante nur mit einer Hälfte auf den Displayschutz. An dem anderen unverklebten Ende kann man nun den bereits aufgebrachten Displayschutz mühelos anheben. Mit einem zweiten Klebestreifen, der zu einem Ring mit der klebenden Seite nach außen zusammengeklebt wurde, wird nun das Staubkorn entfernt.

. A strong 256-bit encryption secures the data transfer. With our externally issued SSL certificate, we are transparent and compliant. In addition to the SSL-secured website, we take data protection very seriously.

. A strong 256-bit encryption secures the data transfer. With our externally issued SSL certificate, we are transparent and compliant. In addition to the SSL-secured website, we take data protection very seriously.