Crystal clear screen protection material

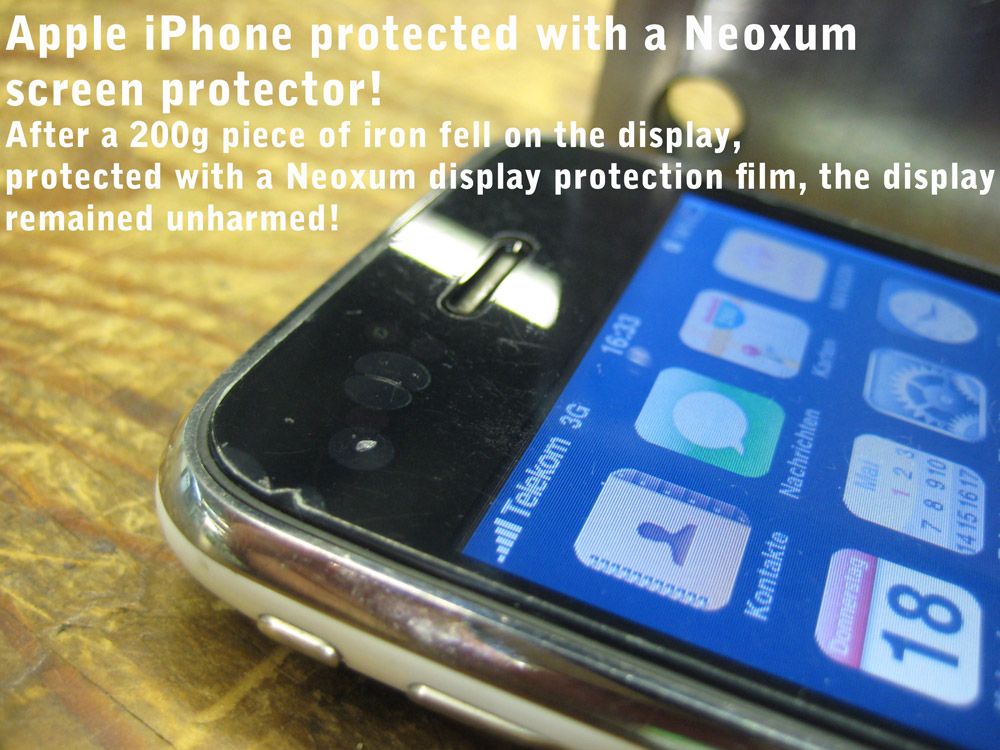

High protective effect of the clear display film

Similar to the anti-reflective display film, the clear display protection film from Neoxum is very durable and robust. A 0.13 mm thick special plastic effectively prevents scratches on the display and mechanical damage. In case of a fall, the transparent film, like the anti-reflective film, protects the display from damage.

Scratch guard

Displays often come into contact with objects such as keys or pens. A globally acting company in the logistics industry relies on our professional display protection for years, equipping the mobile devices, handheld or industrial smartphone device displays of freight delivery or logistics employees with display protection from Neoxum before handing them out to the employees. Also in internal logistics, terminals of forklifts but also tablet PCs and notebooks, which are used in everyday life in warehouses and logistics, are protected by our display protection for a long time. Ask us for references!

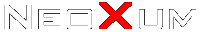

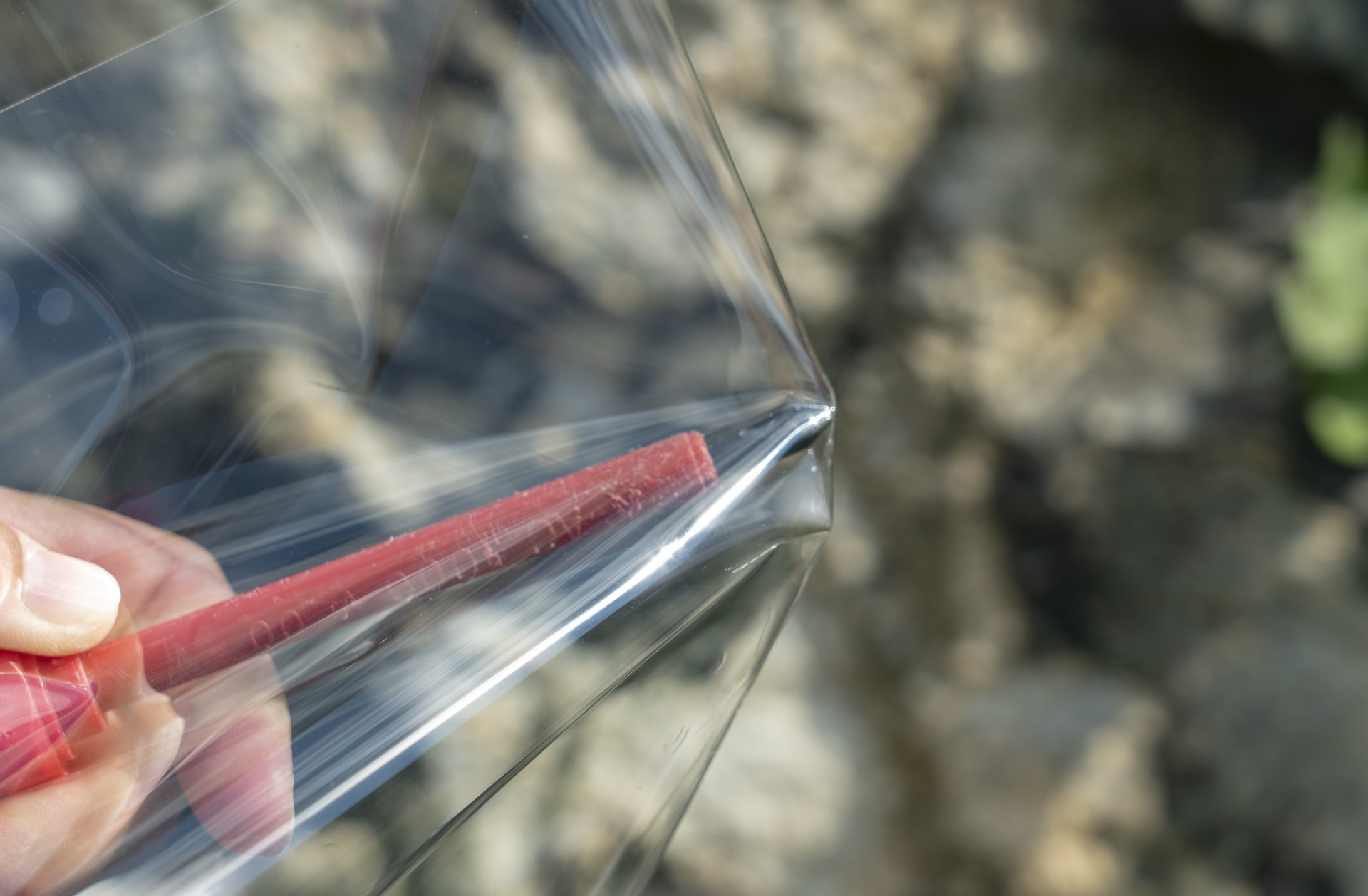

High transparent screen protection film

The AS (Anti Scratch) screen protector from Neoxum protects displays without anti-glare effect. Due to a special polymer, an extremely high transparency of the protective film on the display or monitor is achieved. After application, the transparent film is (almost) invisible and only at the edges you can see that a 0.13 mm thick protective clear scratch protection was applied at all. The product photos of the transparent display film show that there is no perceptible change in the brightness or brilliance of the display. Measured values of the optical behavior prove the subjective perception of the high transparency.

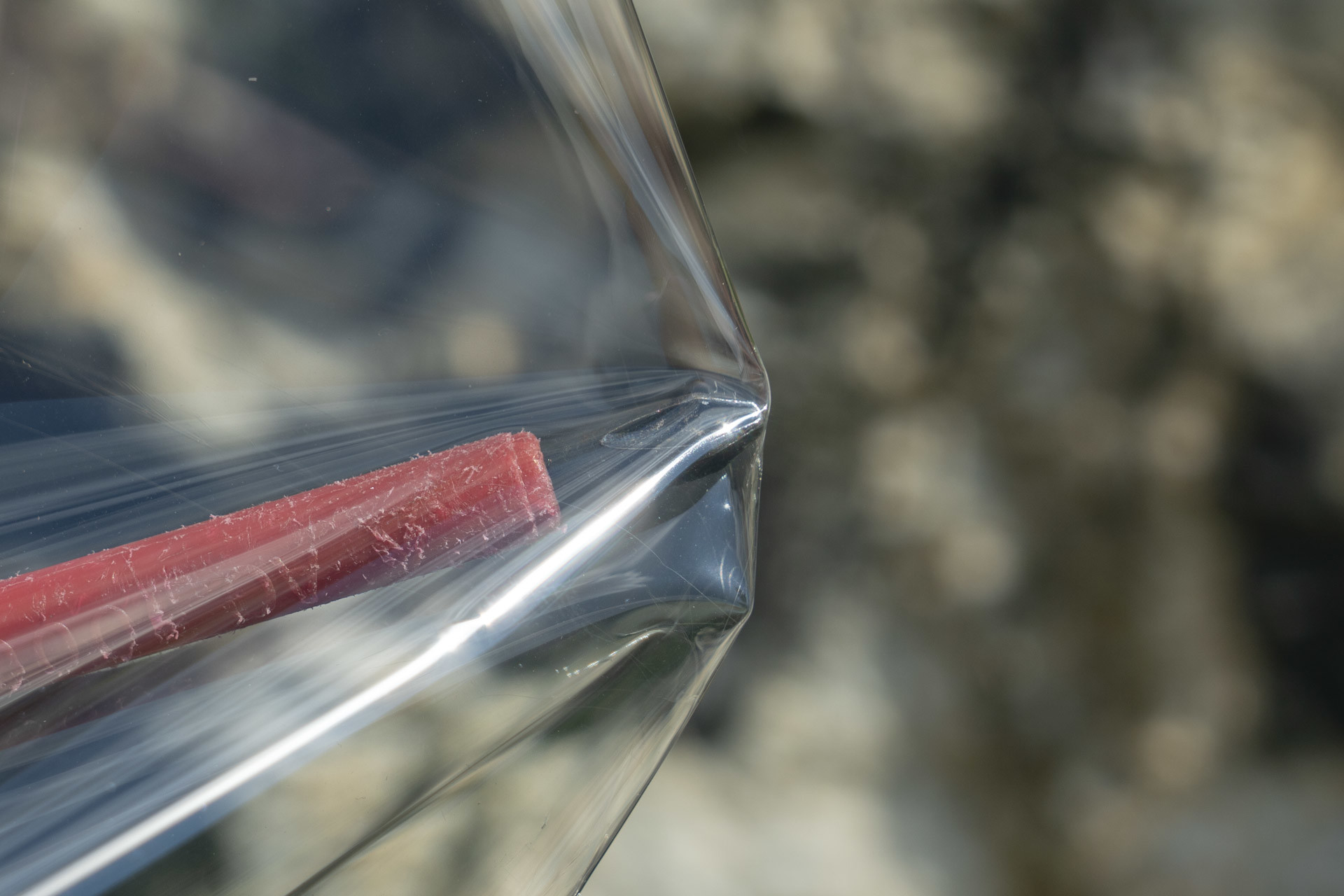

Transparent clear protective film from Neoxum - Measurement data

The light transmission was determined with the aid of UV-VIS spectroscopy, which is usually used to record molecular spectra in order to determine the molecular composition of a substance. In this process, molecules or groups of the substance interact with the energy of the irradiated visible light. If an interaction takes place, part of the energy of the visible light is absorbed by the substance. This absorption of energy is expressed in the UV-VIS spectrum by the fact that the spectrum experiences a downward dip and the transmission is significantly reduced on the Y axis.

In the case of Neoxum's transparent, as well as anti-reflective display films, there is virtually no absorption of energy in the visible range of light between about 400 and 800 nanometers. The films are therefore enormously transparent, especially the ultra-clear screen protectors.

Color authenticity clear display film

As can be seen from the above spectrum in the visible range of light (approx. 400 - 800 nanometers), the transparency is consistently approx. 92 - 94%. This means that no color distortions occur in the visible range and the 0.13 mm thick display film is extremely light-transmissive. Only the thickness of 0.13 mm is responsible for a small part of the light being absorbed. This minimal absorption can be compensated very easily by a minimal brightness adjustment of the display. Internal tests and a lot of feedback from our customers, such as a global publishing house that has purchased thousands of display protection films for Apple iMac devices, are completely and exclusively positive regarding the light transmission and brightness of the display with Neoxum display protection applied. Also many photographers from the hobby and professional area report that Neoxum display films do not falsify the color fastness and the brightness of the display does not play a role. The focus is on perfect scratch protection for sensitive camera displays.

-35 °C up to 110 °C

High temperature resistance

Both the anti-glare film and the crystal-clear display film from Neoxum are extremely temperature-resistant. Neoxum industrial-grade display protection films are temperature resistant between -35 °C and +110 °C, protecting sensitive displays in cold areas, such as outdoors or at companies operating in the freezer sector, as well as hot conditions, such as industrial panels in steel production.

Independent tests by our customers in the cold chamber show that Neoxum display films function perfectly even after extreme temperature loads and reliably protect touchscreens or displays from mechanical damage even in cold conditions. Due to the special polymer, our protective films remain dimensionally stable and flexible at high temperatures or cold temperatures. Display protection based on pure glass, such as typical bulletproof glass, becomes brittle at low temperatures and can shatter more easily. The anti-glare film retains the anti-reflective property of the film surface even after many stress cycles. Our transparent and crystal-clear display protection film retains its high transparency and does not become cloudy even after many stress cycles.

Adhesion effect display protection Neoxum

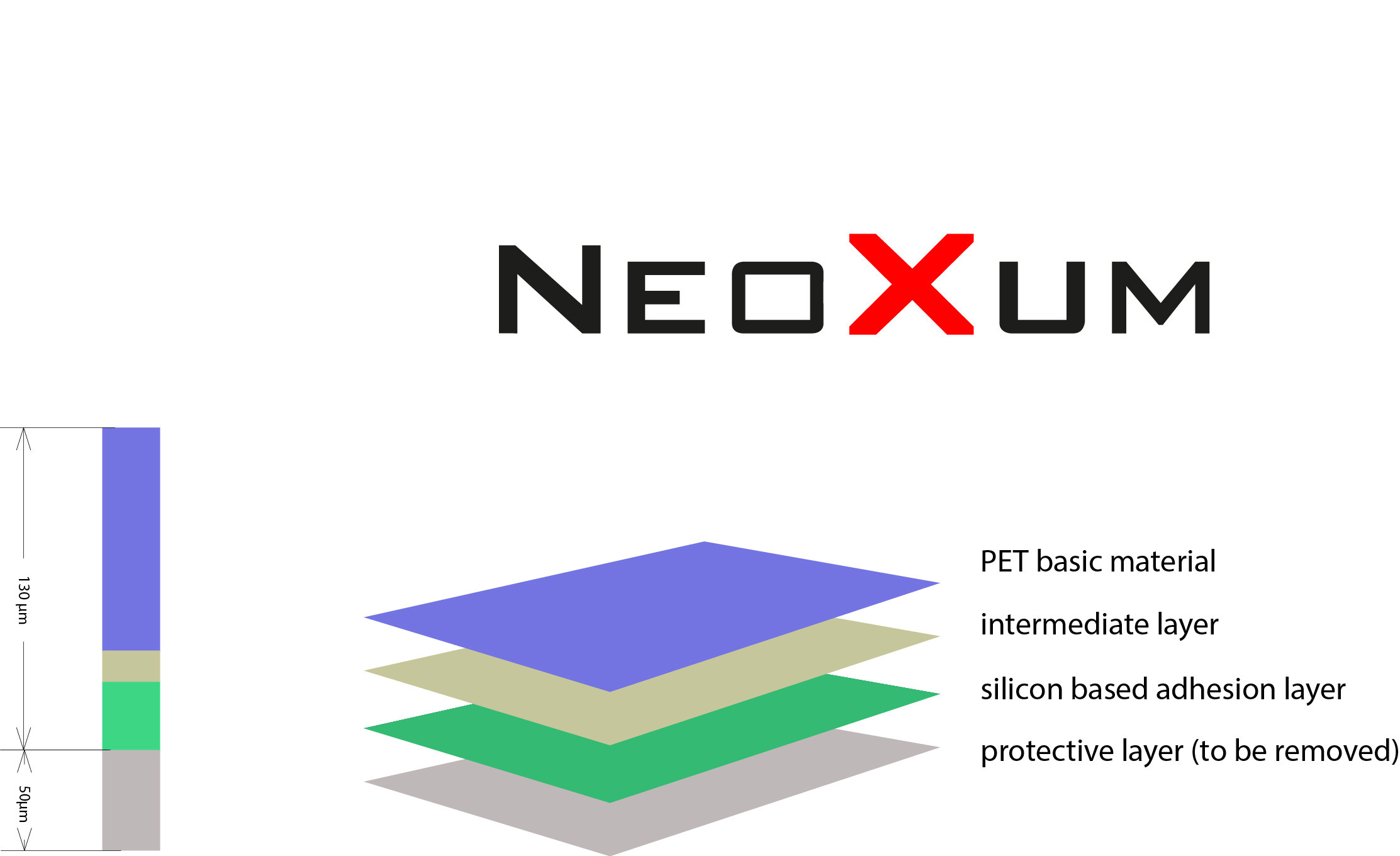

Adhesion of the Neoxum screen protector

Our display protection films adhere exclusively via physical adhesion forces. Neoxum films "stick" to the surface via a kind of "suction foot in the nanometer range". No adhesive is used, which would lose its adhesion very quickly under UV radiation, cold and heat. This Adhesion is a fundamental phenomenon in the molecular range that is created by interactions of interfaces. The silicone layer of the Neoxum film ensures that the protective film adheres very well to almost all smooth materials, such as plastics, glass, painted surfaces but also polished metals.

Removable without residue

Neoxum films can be easily removed from all substrates without leaving any residue.

Technical datasheet Neoxum screen protection film

Datasheet of the anti-glare screen protectiion film and the transparent display protective foil

Your question

We will be happy to answer any specific questions you may have about our products, in particular about the clear display film. With the support of our more than 15 years of experience, we have already implemented many challenging projects for our customers. Our competence in the field of professional display protection films is based on a deep understanding of materials, our own product development and a high affinity to develop solutions for the requirements of our customers. We manufacture cstomized films on our laser equipment at our production site in Bavaria, Germany.

. A strong 256-bit encryption secures the data transfer. With our externally issued SSL certificate, we are transparent and compliant. In addition to the SSL-secured website, we take data protection very seriously.

. A strong 256-bit encryption secures the data transfer. With our externally issued SSL certificate, we are transparent and compliant. In addition to the SSL-secured website, we take data protection very seriously.