OnScreen ® Hybridglas antireflektierende Oberfläche

OnScreen® Hybridglass grade protection with anti-glare surface coating

OnScreen ® is a Neoxum brand

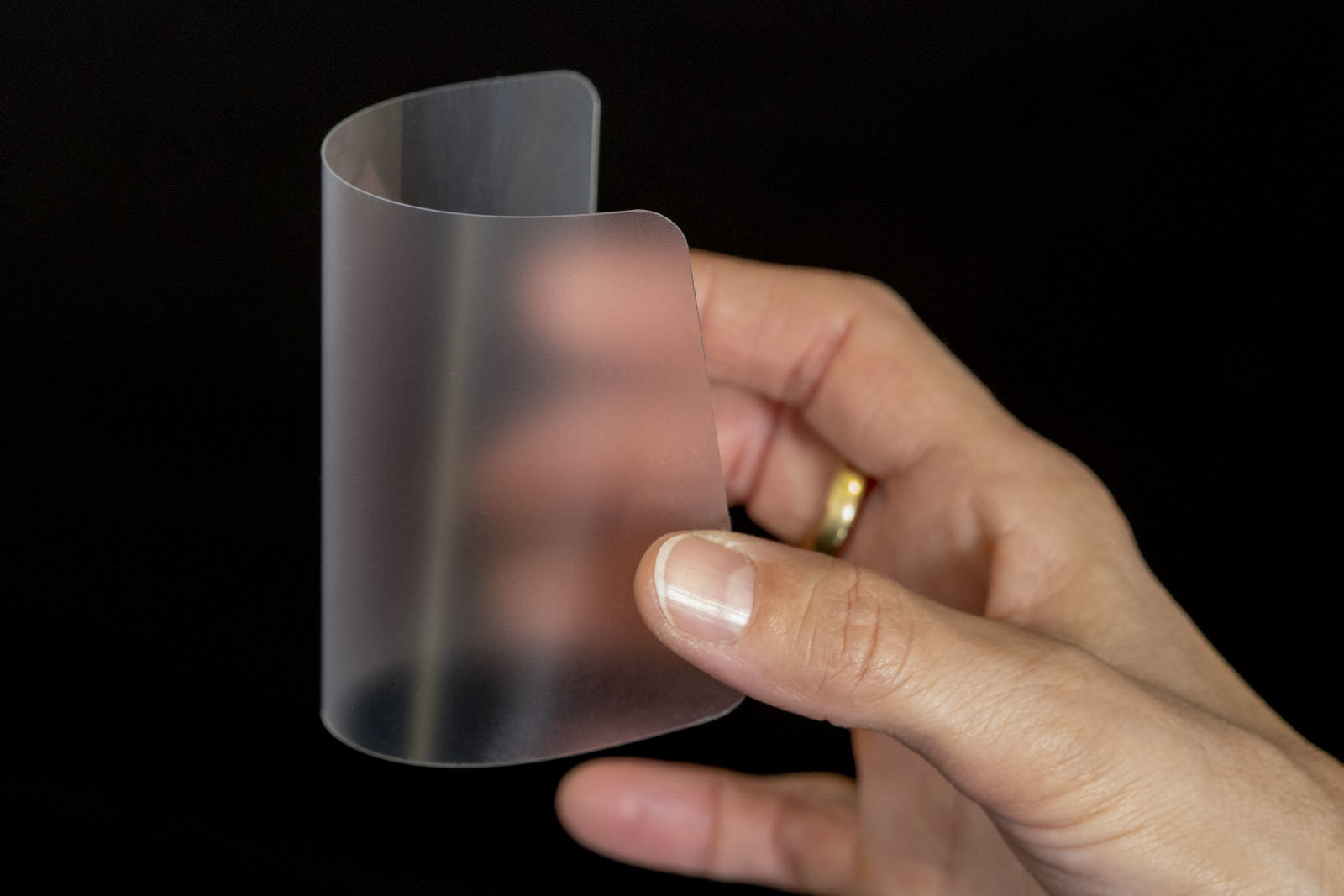

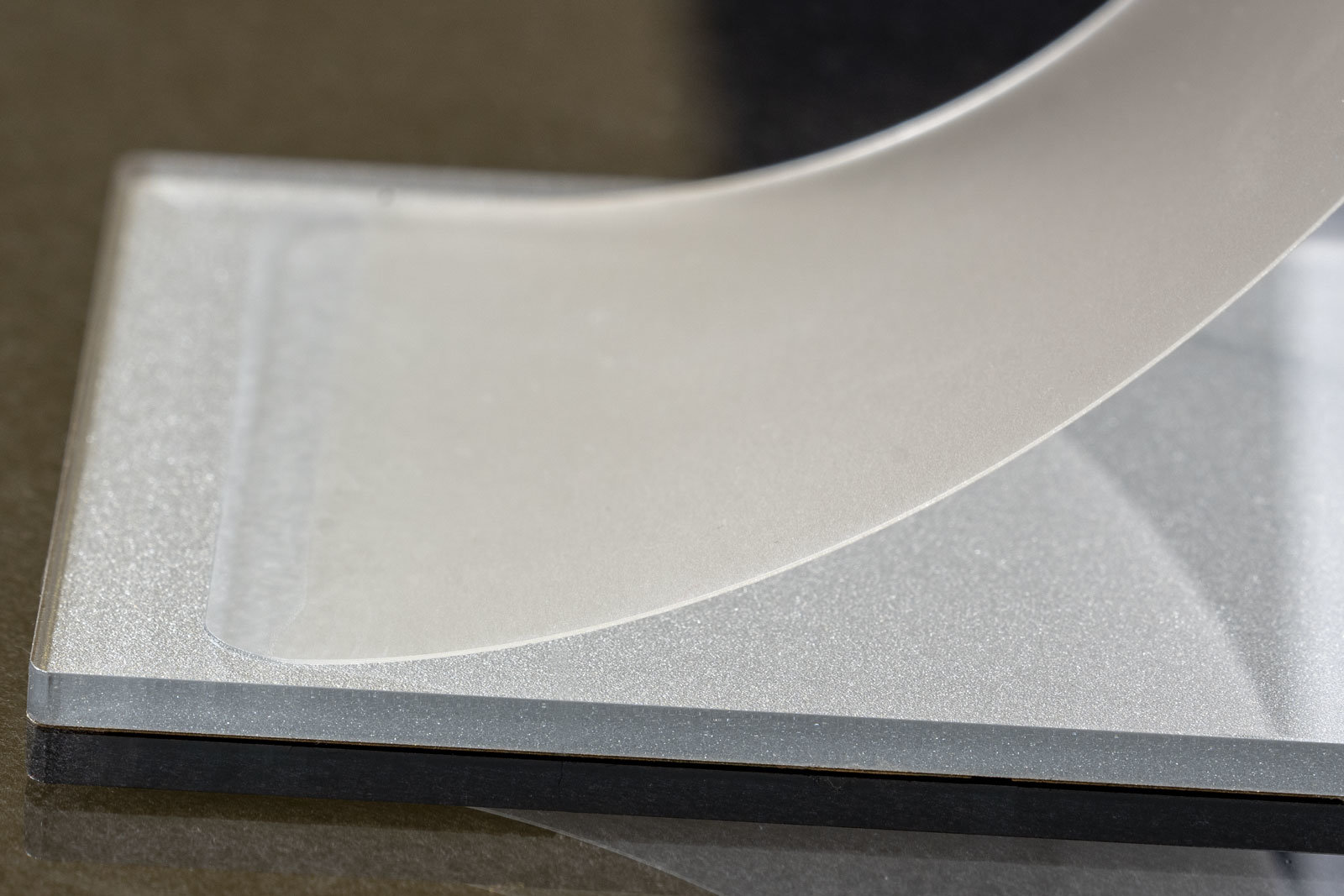

Antireflektierendes Hybriglas ist so hart wie Glas und dennoch flexibel wie Folie. OnScreen® Hybridglas mit entspiegelnder Oberflächenbeschichtung ist ein extrem widerstandsfähiger flexibler Verbund aus Glas und Spezialpolymer. Die glasharte Oberfläche mit Antiblendbeschichtung wird mit der Flexibilität einer Folie kombiniert. Die harte Oberfläche von 7H nach ISO 15184 garantiert effizienten Kratzschutz von empfindlichen Displays und Oberflächen. Die Flexibilität sorgt dafür, dass OnScreen ® Hybridglas nicht splittert oder bricht. Auch die Montage auf glatten Oberflächen, wie Displays, Glas, Kunststoff oder Metall ist kinderleicht durch die homogene adhäsive Silikonhaftschicht. Blasenfreies Aufbringen wird garantiert. OnScreen ® Hybridglas lässt sich jederzeit rückstandsfrei entfernen. Die Haftwirkung ist trotzdem enorm hoch, so dass die flexible und dennoch harte Schutzschicht nicht verrutscht. Oberflächen werden mit Hilfe der glas-harten Antireflex Schicht vor Kratzern und mechanischen Beschädigungen geschützt. OnScreen® Hybridglas ist unserer Meinung nach der perfekte Kratzschutz und zerbrechlichem Panzerglas überlegen. Neben der antireflektierenden Variante (Bezeichnung MHG für mattes Hybridglas) gibt es unser hybrides Glas Folien Material als glasklare Variante (Bezeichnung CHG für clear Hybridglas)

-30 °C up to 140 °C

High temperature resistance

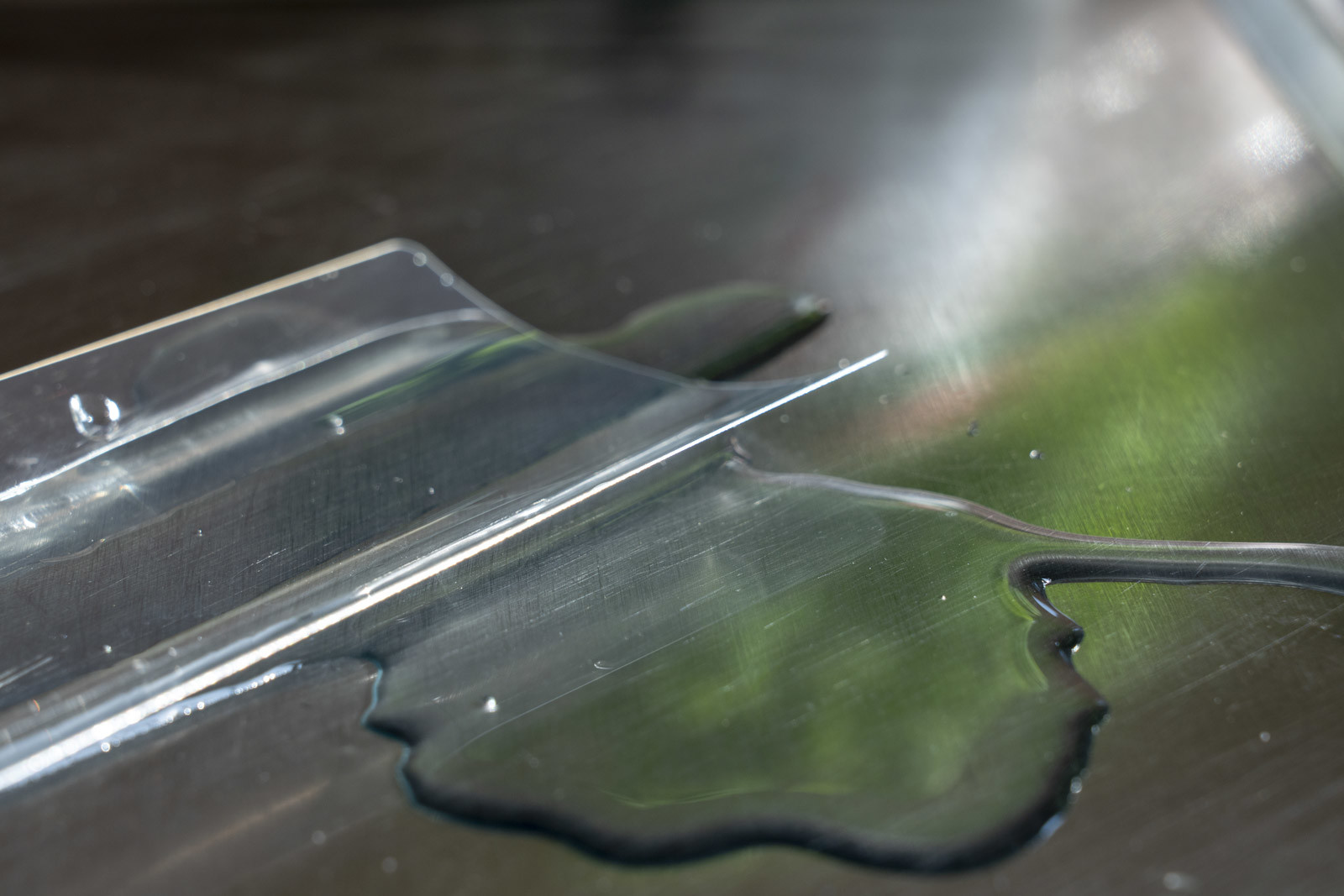

Both the anti-glare film and the crystal-clear display film from Neoxum are extremely temperature-resistant. Hybrid glass is even more temperature-resistant. Tests have shown that the flexible and glass-hard display protection material is stable in a temperature range from -30 °C to +140 °C. OnScreen ® Hybrid glass with anti-glare effect protects displays (and touch displays) from damage and scratches in cold to very cold environments, such as outdoor winter or deep-freeze environments. Under extremely hot conditions, such as industrial panels in heavy industry or surfaces that are permanently exposed to high temperatures, such as photovoltaic panels, OnScreen ® hybrid glass from Neoxum remains absolutely dimensionally stable. Clear hybridglas also shows identical high temperature resistance.

OnScreen® Hybridglas extreme testing

In nachfolgendem Test (es wurde nichts gefakt, retouchiert oder manipuliert!) haben wir ein transparentes Hybridglas extremen Funkenflug (Hitze) und einer anschließenden mechanischen Belastung (Hammerschlag) ausgesetzt. Genauso gut hätten wir ein mattes antireflektierendes Hybridglas im Test verwenden können.

Test report chemical resistance and temperature resistance of OnScreen ® Hybridglas

Download OnScreen ® Hybridglas test reports chemical and temperature resistance

In our Blog post, we had already reported on the availability of the detailed test report on chemical resistance and temperature resistance.

Adhesion effect display protection Neoxum

Adhesion forces OnScreen® Hybridglass

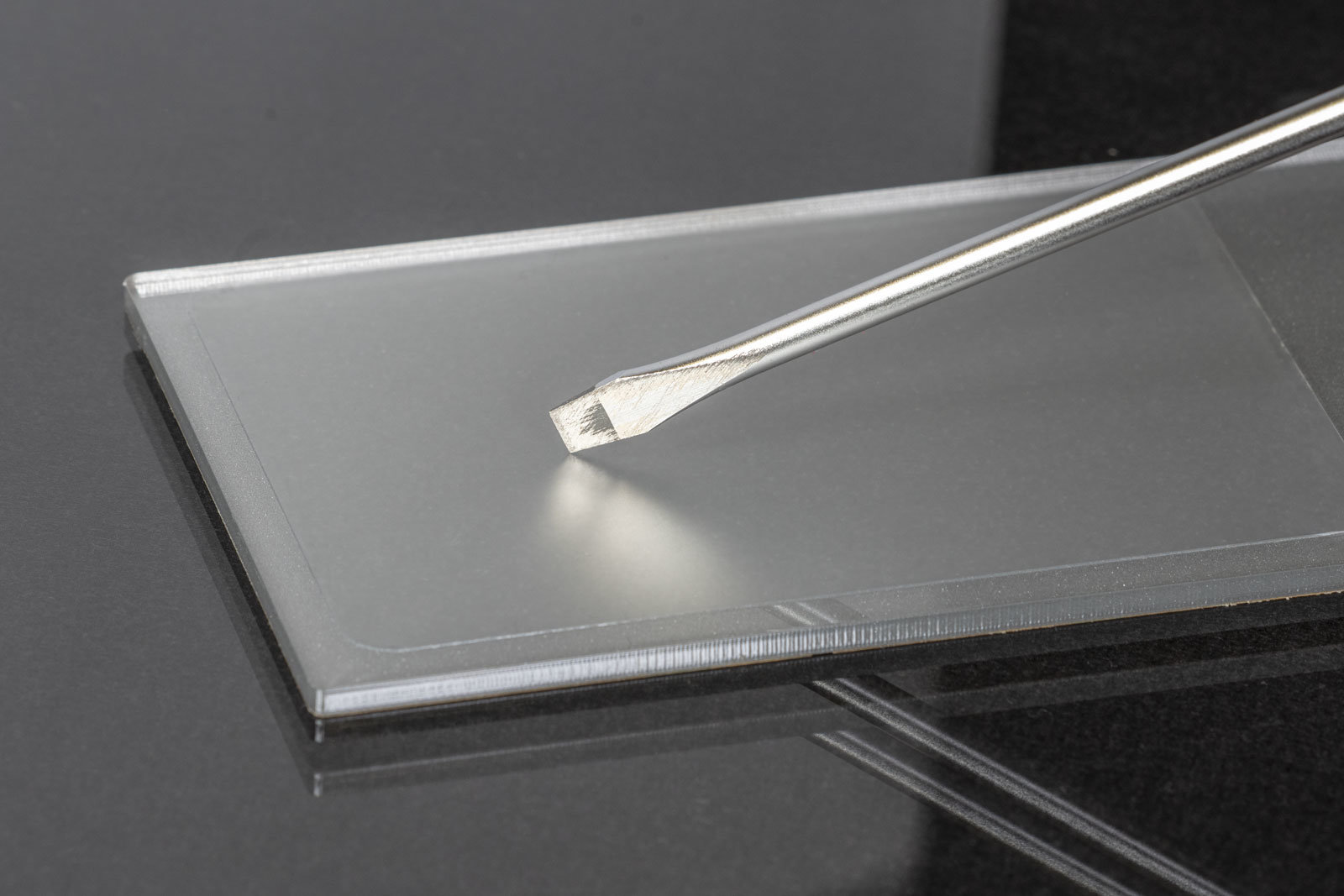

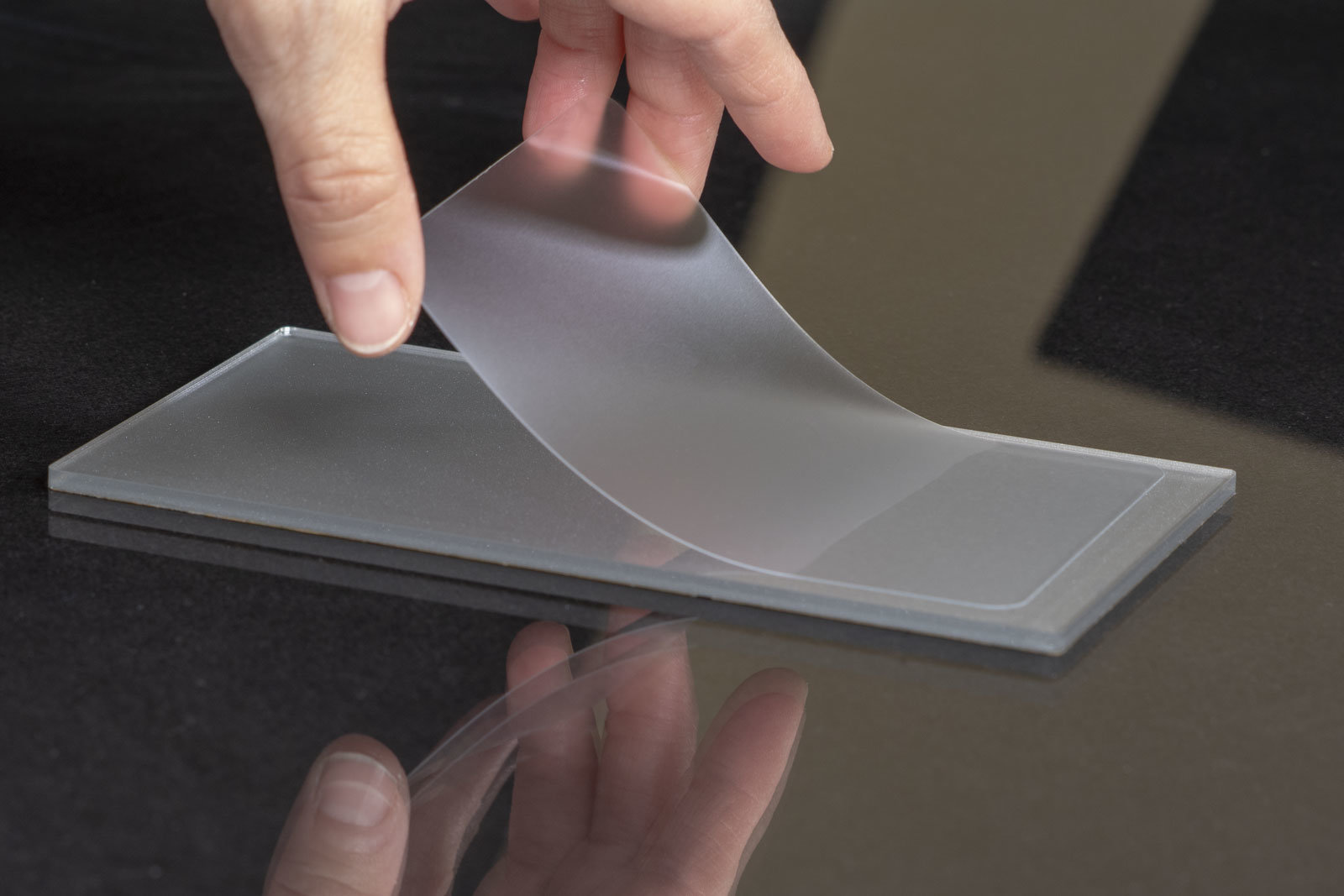

Analog zu unseren Antireflex Displayschutzfolien oder glasklaren Displayschutzfolien haften OnScreen ® Hybridgläser ausschließlich über physikalische Adhäsionskräfte. Die silikonisierte Unterseite des Hybridglases haftet mit Hilfe einer Art Saugfuß im Nanometerbereich an glatten Oberflächen, wie Glas, Kunststoffen, polierten Metallen und auch lackierten Oberflächen. Der Verzicht auf Klebstoff hat den Vorteil, dass die Haftung reversibel und zugleich so stark ist, dass ein aufgebrachtes Hybridglas – es spielt dabie keine Rolle ob mattiert oder glasklar, niemals unter normalen Bedingungen verrutscht oder gar abfällt. Weder Kälte noch hohe Temperaturen vermindern die Haftung auf glatten Oberflächen. Eine Alterung, wie bei Acrylat Klebstoffen, ist nicht zu beobachten. OnScreen ® Hybridglas ist perfekt für den Einsatz in der Industrie geeignet. Unser Hybridglas splittert und zerbricht nicht, so dass auch ganz spezielle Anforderungen, z.B. aus der Lebensmittelbranche oder der Medizintechnik erfüllt werden können. Wir sind der Meinung, das unser Hybridglas dem Panzerglas überlegen ist.

Aber auch als Kratzschutz für Handy, Kamera und Touchscreen sind die flexiblen Glasfolien – in den Ausführungen klar oder antireflektierend – bestens geeignet. Neoxum produziert OnScreen ® Hybridglas bis zu einer Größe von 1000 x 800 mm (ca. 55 Zoll Diagonale) in nahezu jeder beliebigen Form (sehr enge Radien müssen vorab getestet werden) und Menge kundenindividuell. Individuelle Gravuren, wie Inventarnummer, Namen, Logos oder Schriftzüge sind on top möglich.

Haftung / Klebkraft Neoxum Displayschutz

Adhäsionskräfte auf Oberflächen

Neoxum Displayschutzfolien und unser OnScreen ® Hybridglas haften rein über physikalische Adhäsion d.h. die Folien saugen sich über eine Art “Saugfuß im Nanometerbereich“ am Display an, ohne jeglichen Einsatz von Klebern oder Klebstoffen, fest. Beim Entfernen von Neoxum Displayschutz Folien oder Hybridglas vom Display bleiben keinerlei Rückstände auf dem Display zurück.

Physical Chemical Forces

Genauer gesagt spielen mehrere physikalisch-chemische Kräfte eine Rolle. Die Adhäsion ist ein grundlegendes Phänomen im molekularen Bereich, die durch polare Wechselwirkungen an Grenzflächen entstehen, in unserem Fall der Grenzfläche Displayoberfläche Silikonhaftschicht der Neoxum Displayfolie, bzw. OnScreen ® Hybridglas, sogenannte Van-der-Waals Bindungen zwischen Molekülen der Displayoberfläche und Molekülen der Adhäsionsschicht (der sehr dünnen Silikonhaftschicht). Der entschiedene Faktor bei Adhäsion ist dabei die räumliche Nähe der beiden Oberflächen. Die Silikon Adhäsionsschicht von Neoxum Displayschutz, bzw. Oberflächenschutz, ist so geartet, dass unsere Displayfolien, sowie unser Hybridglas, auf vielen glatten Materialien, wie Kunststoffen, Metallen aber auch Glas sehr gut haften. Von allen Materialtypen lässt sich die Adhäsionsfolie und das Hybridglas rückstandsfrei wieder entfernen.

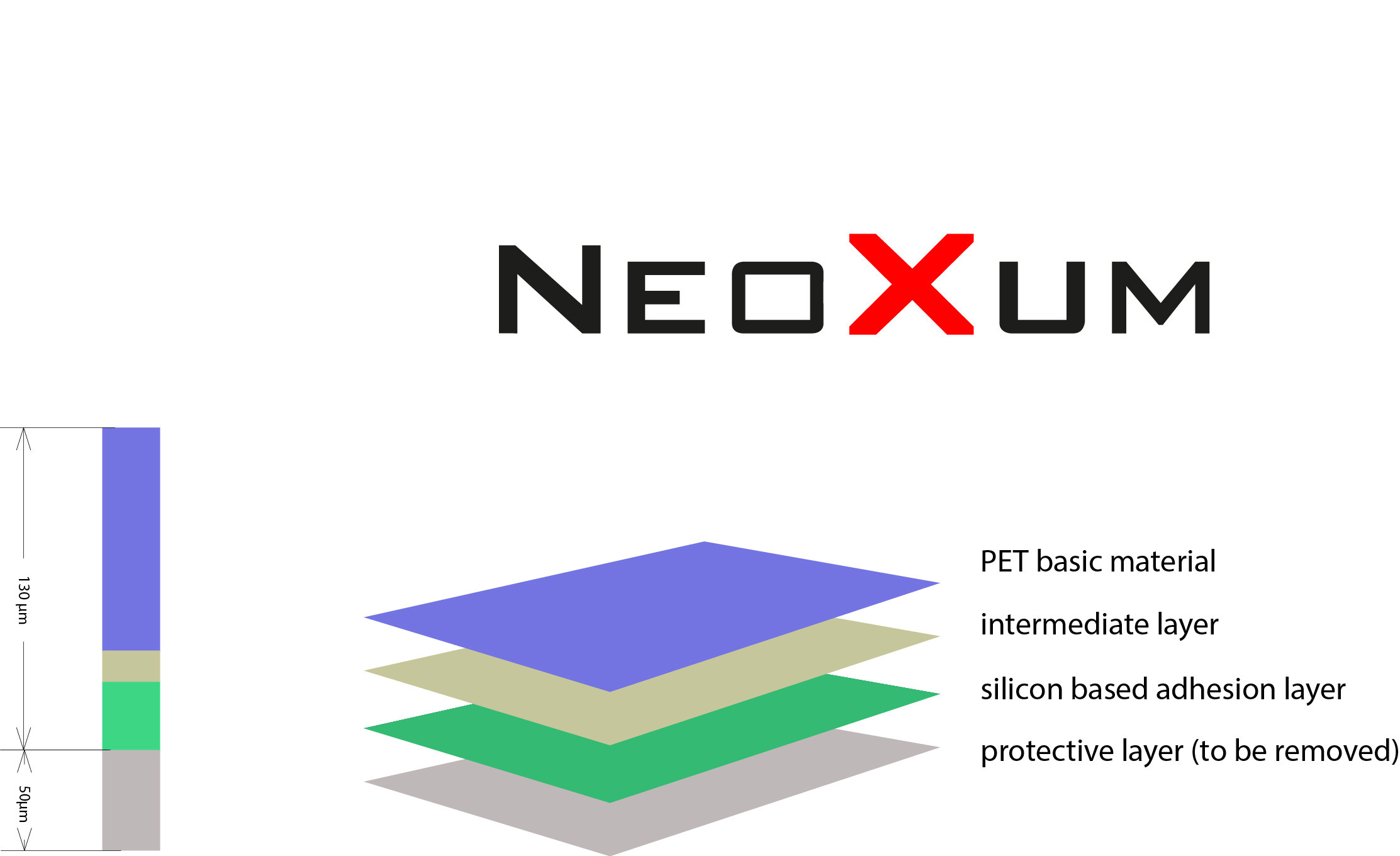

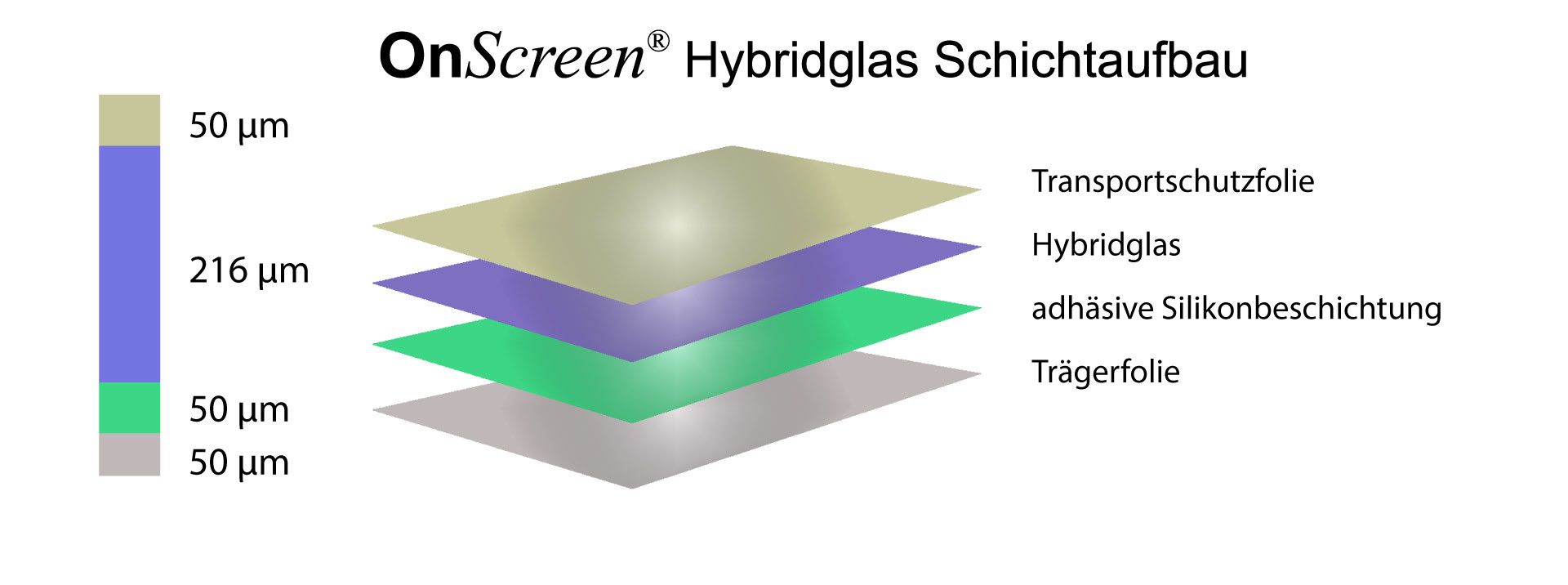

Schichtaufbau Neoxum Schutzfolie

Schichtaufbau OnScreen ® Hybridglass

Why is that

Commercially available simple adhesive films usually have an adhesive layer made of acrylate adhesive or modified acrylate. This adhesive layer exerts much stronger physical bonds than the adhesive forces of the adhesive films. This type of acrylic adhesive film usually CANNOT be removed from displays without leaving residue after a few weeks or months of use.

Removable without residue

Von allen Untergründen kann OnScreen ® Hybridglas mattiert problemlos und rückstandsfrei wieder entfernt werden.

. A strong 256-bit encryption secures the data transfer. With our externally issued SSL certificate, we are transparent and compliant. In addition to the SSL-secured website, we take data protection very seriously.

. A strong 256-bit encryption secures the data transfer. With our externally issued SSL certificate, we are transparent and compliant. In addition to the SSL-secured website, we take data protection very seriously.