OnScreen ® Hybridglass

OnScreen® Hybridglass protects your value

OnScreen ® is a Neoxum brand

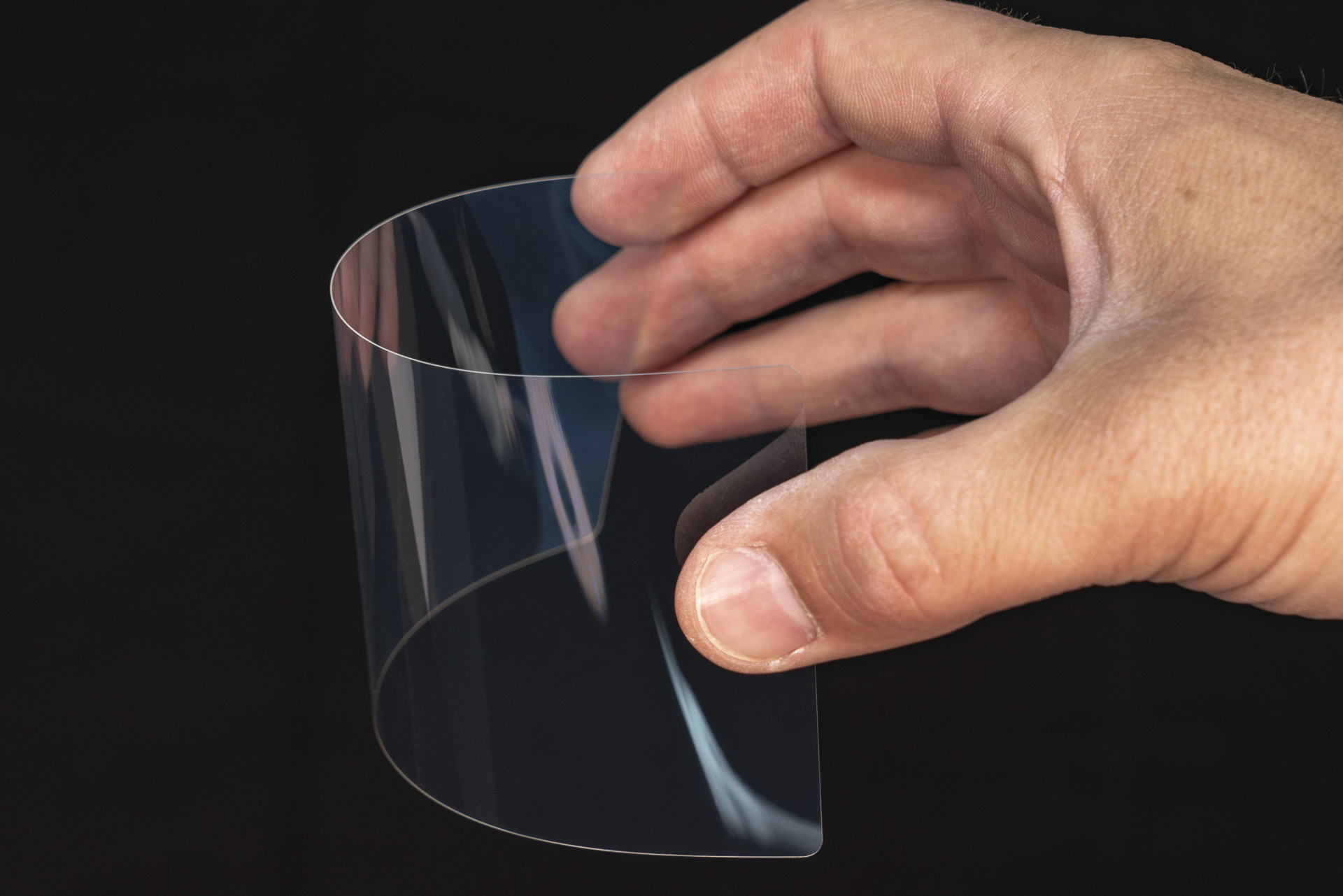

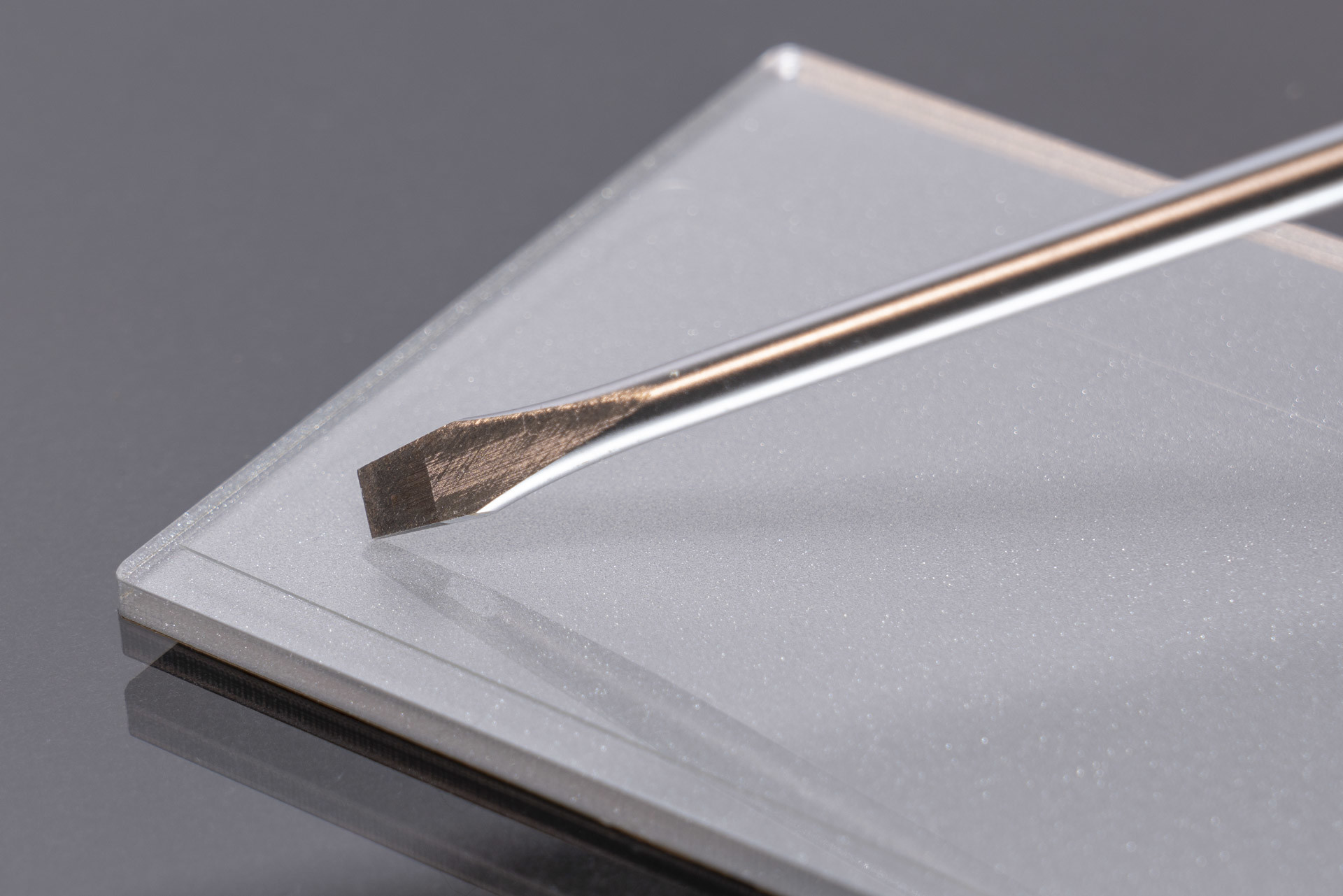

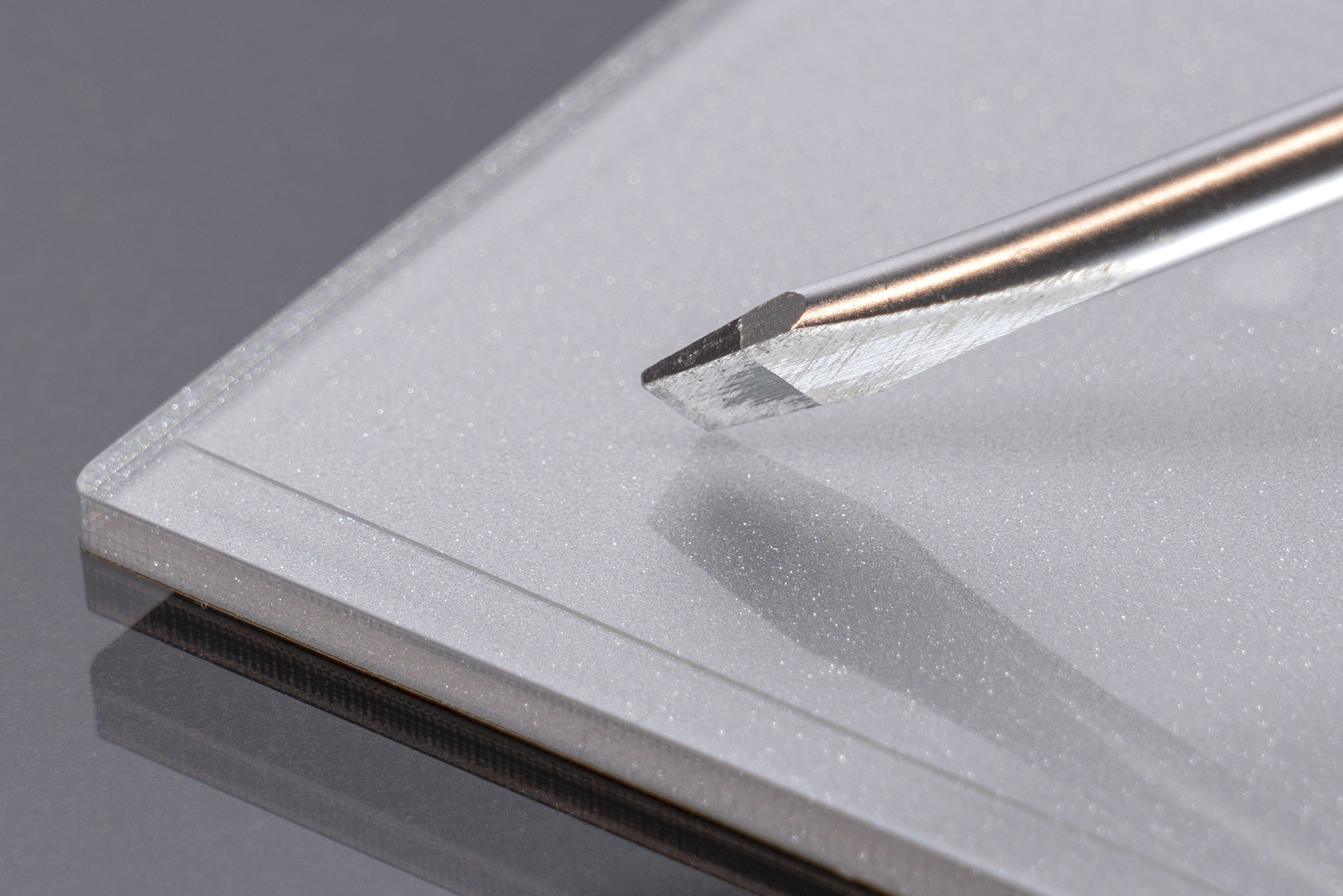

OnScreen ® Hybridglass is an extremely resistant and flexible composite of glass and special polymer with the flexibility of a film combined with the hard surface of glass. The hard surface of up to 9H according to ISO 15184 guarantees efficient scratch protection of sensitive displays and surfaces. Hybrid glass is the perfect combination of the properties of transparent glass and the flexibility of a plastic film. The result is a very flexible bendable and transparent surface protection that has a glass hard surface and yet is elastic enough not to shatter like glass. Equipped with a thin silicone layer, OnScreen® Hybrid Glass films adhere perfectly to all smooth surfaces made of plastic, glass or metal without leaving any residue when removed later. Touch surfaces are effectively protected from scratches and mechanical damage. In our opinion, hybrid glass is the perfect scratch protection and superior to fragile bulletproof glass, many times called "Panzerglas".

High transparancy of the OnScreen® Hybridglass

OnScreen ® At 0.22 mm overall thickness, hybrid glass is very strong and therefore extremely robust. Nevertheless, the flexible glass is highly transparent and crystal clear. Screen contents are displayed naturally. Colors are not distorted. The hybrid glass is ideally suited for demanding tasks.

If an application on the display can no longer be read well or at all in direct sunlight, we recommend using the similarly robust anti-reflective hybrid glass with a matte surface coating.

Measured transmission of light

The light transmission was determined according to ASTM D 1003. The measurement data show a transparency of up to 95%, which means that the human eye can see virtually no difference with and without hybrid glass in terms of light transmission. Just glass!

Optical properties of OnScreen ® Hybridglass

The color authenticity of OnScreen® hybrid glass is enormously high. A key property of glass is its light transmission in the spectrum that is optically visible to humans, approx. 400 to 800 nanometers. In addition, glass exhibits excellent properties with regard to color accuracy. Due to the amorphous structure of glass, which in combination with a highly transparent special polymer, results in an extremely high color consistency: colors of the screen or display, or touch screen are completely preserved and are not distorted or the color spectrum shifted. Feedback from customers in the world of photography or graphics confirm the outstanding optical properties. Customers from the industrial sector, who use the very hard surface and flexibility of the hybrid glass, for example in their production on touchscreens, panels or terminals, are also convinced by the color reproduction.

-30 °C up to 140 °C

High temperature resistance

Both the anti-glare film and the enormously transparent display film from Neoxum are extremely temperature-resistant. OnScreen® Hybrid Glass is also very temperature resistant. Tests have shown that the flexible and glass-hard display protection material is stable in a temperature range from -30 °C to +140 °C. Industrial-grade OnScreen® Hybrid Glass protects sensitive displays in winter or cold storage, as well as hot conditions, such as industrial panels in welding or printing industries. Neoxum OnScreen® Hybrid Glass remains absolutely dimensionally stable at high temperatures or cold. The flexible and crystal clear non-splintering alternative to bulletproof glass retains its high transparency and does not become cloudy even after many loads.

OnScreen® Hybridglas extreme testing

Heat test with an abrasive cutter grinding off a metal block. The OnScreen hybrid glass withstands extreme flying sparks. Subsequently, extreme test with a hammer blow on the hybrid glass, which was applied to a plexiglass carrier.

Test report chemical resistance and temperature resistance of OnScreen ® Hybridglas

Download OnScreen ® Hybridglas test reports chemical and temperature resistance

In our Blog post, we had already reported on the availability of the detailed test report on chemical resistance and temperature resistance.

Adhesion effect display protection Neoxum

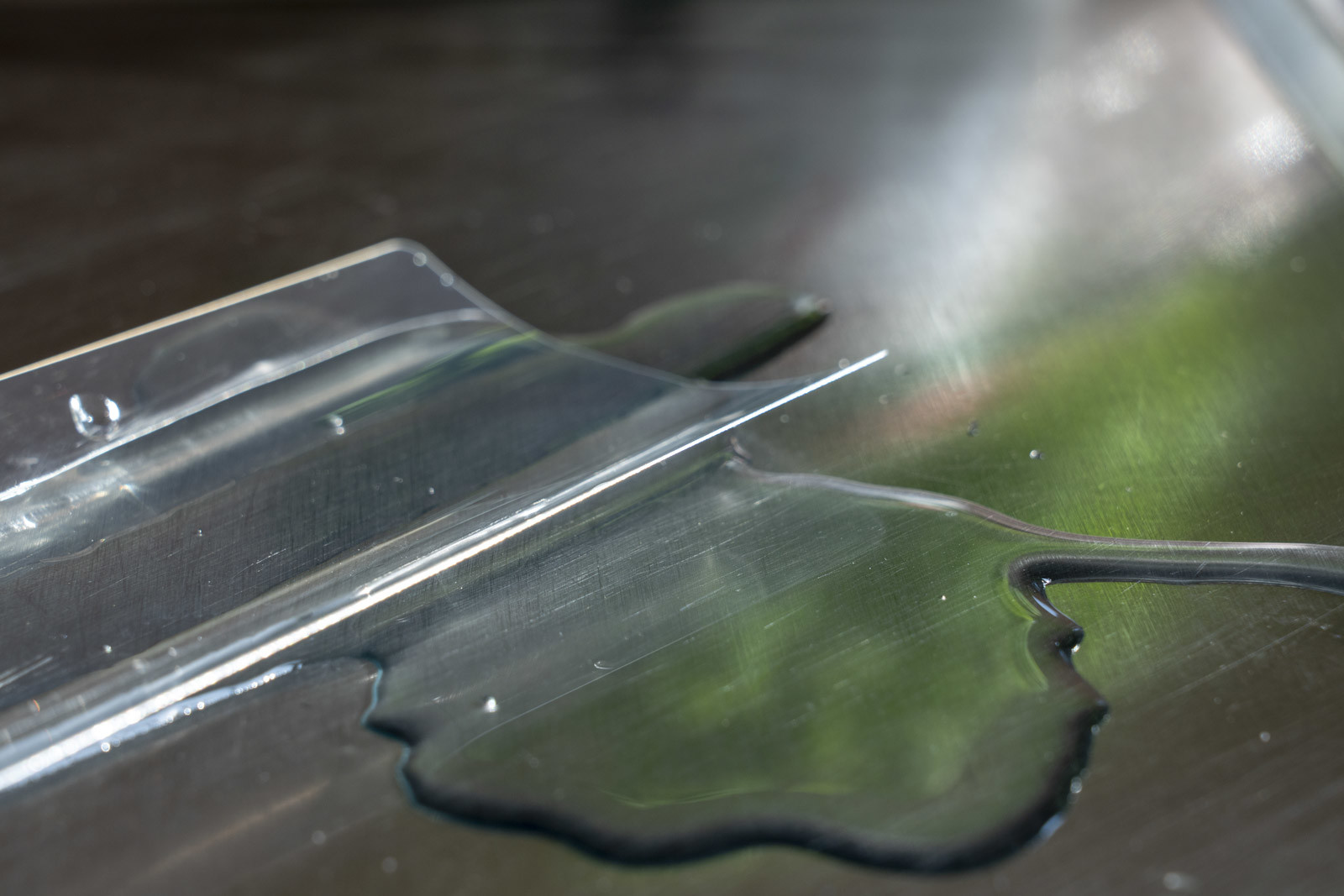

Adhesion forces OnScreen® Hybridglass

Analogous to our anti-reflective protection films or crystal-clear display protection films, OnScreen® hybrid glasses adhere exclusively via physical adhesion forces. The siliconized underside of the hybrid glass adheres to smooth surfaces such as glass, plastics, polished metals and even painted surfaces with the help of a kind of suction pad in the nanometer range. The advantage of not using adhesives is that the adhesion is reversible and at the same time so strong that an applied hybrid glass will never slip under normal conditions. Neither cold nor high temperatures reduce adhesion to smooth surfaces. Aging, as with acrylic adhesives, is not observed. OnScreen® hybrid glasses are perfect for industrial applications. But the flexible glass films are also suitable as scratch protection for cell phones, cameras and touchscreens. Neoxum produces OnScreen® Hybrid glasses up to a size of 1600 x 1000 mm (approx. 85 inch diagonal) in almost any shape (very tight radii must be tested in advance) and quantity customized.

Haftung / Klebkraft Neoxum Displayschutz

Adhäsionskräfte auf Oberflächen

Neoxum Displayschutzfolien und unser OnScreen ® Hybridglas haften rein über physikalische Adhäsion d.h. die Folien saugen sich über eine Art “Saugfuß im Nanometerbereich“ am Display an, ohne jeglichen Einsatz von Klebern oder Klebstoffen, fest. Beim Entfernen von Neoxum Displayschutz Folien oder Hybridglas vom Display bleiben keinerlei Rückstände auf dem Display zurück.

Physical Chemical Forces

Genauer gesagt spielen mehrere physikalisch-chemische Kräfte eine Rolle. Die Adhäsion ist ein grundlegendes Phänomen im molekularen Bereich, die durch polare Wechselwirkungen an Grenzflächen entstehen, in unserem Fall der Grenzfläche Displayoberfläche Silikonhaftschicht der Neoxum Displayfolie, bzw. OnScreen ® Hybridglas, sogenannte Van-der-Waals Bindungen zwischen Molekülen der Displayoberfläche und Molekülen der Adhäsionsschicht (der sehr dünnen Silikonhaftschicht). Der entschiedene Faktor bei Adhäsion ist dabei die räumliche Nähe der beiden Oberflächen. Die Silikon Adhäsionsschicht von Neoxum Displayschutz, bzw. Oberflächenschutz, ist so geartet, dass unsere Displayfolien, sowie unser Hybridglas, auf vielen glatten Materialien, wie Kunststoffen, Metallen aber auch Glas sehr gut haften. Von allen Materialtypen lässt sich die Adhäsionsfolie und das Hybridglas rückstandsfrei wieder entfernen.

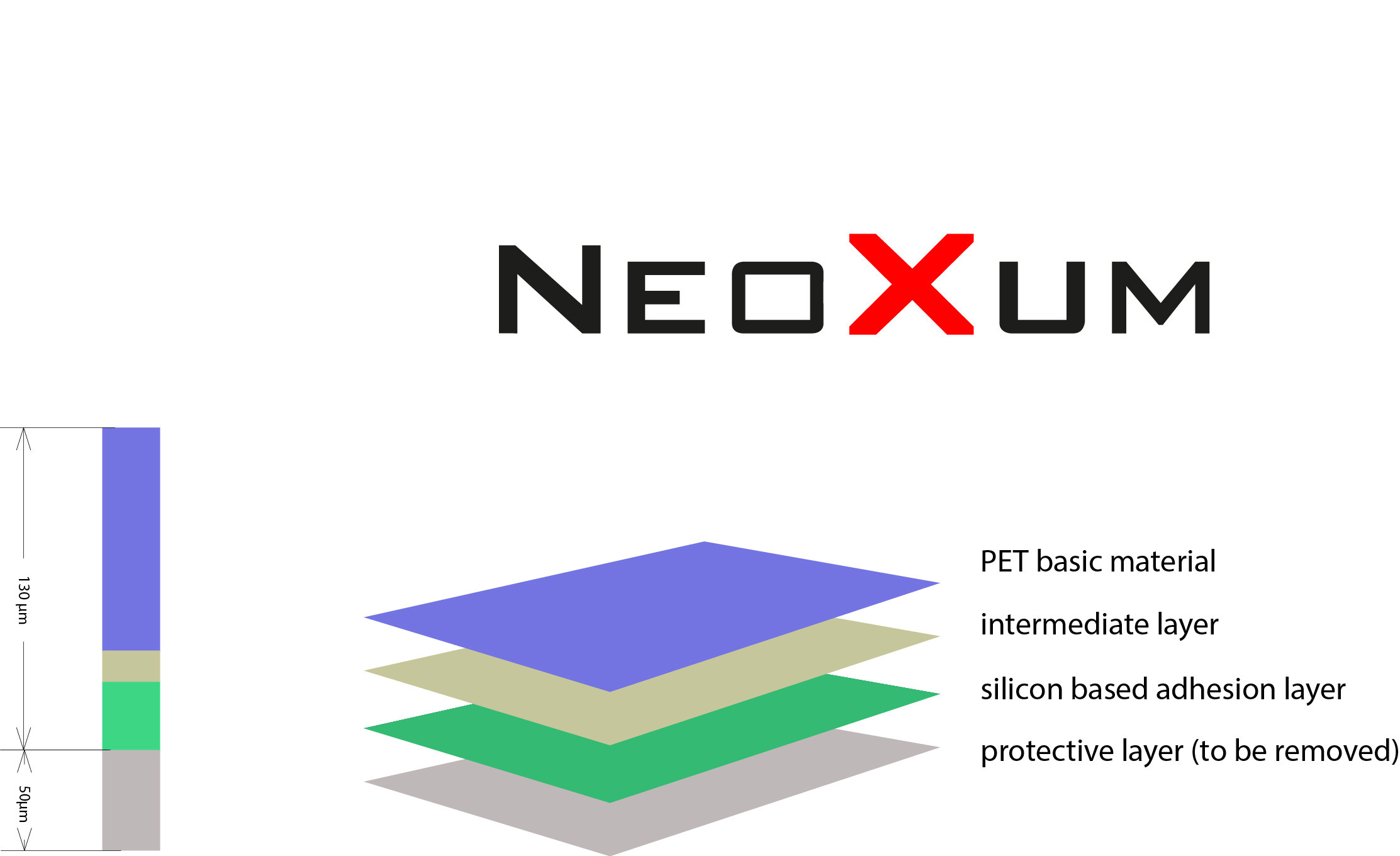

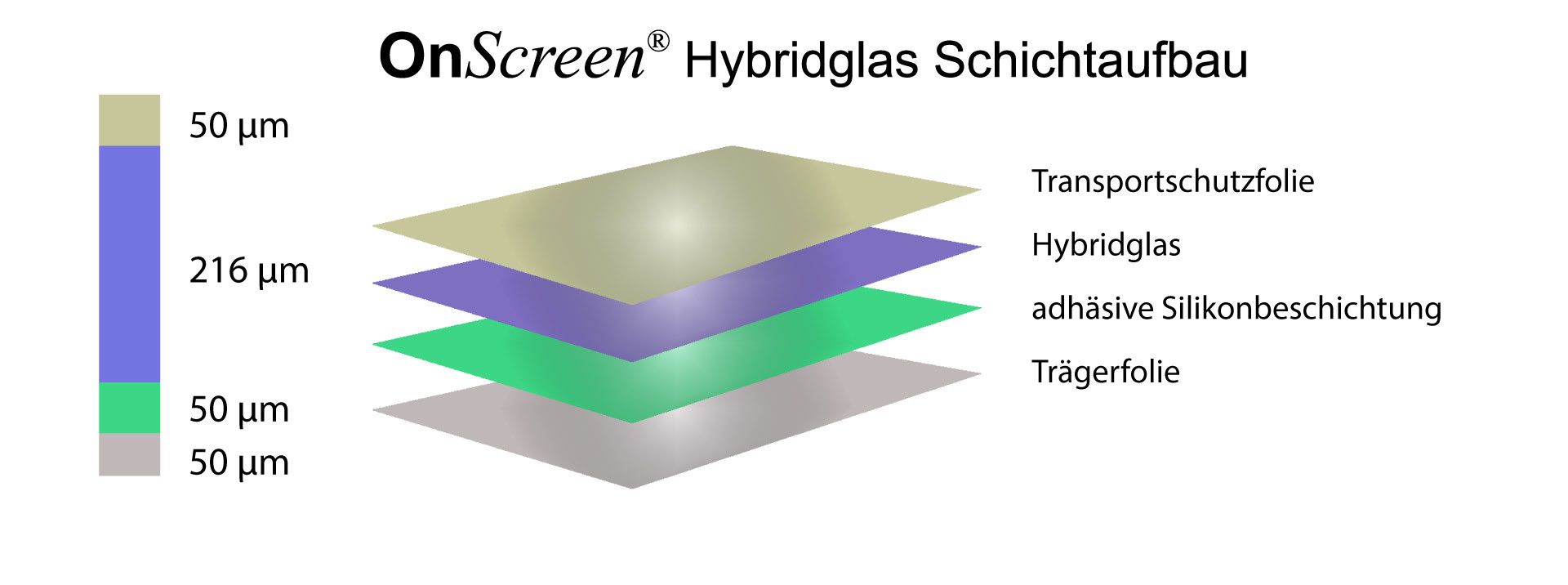

Schichtaufbau Neoxum Schutzfolie

Schichtaufbau OnScreen ® Hybridglass

Why is that

Commercially available simple adhesive films usually have an adhesive layer made of acrylate adhesive or modified acrylate. This adhesive layer exerts much stronger physical bonds than the adhesive forces of the adhesive films. This type of acrylic adhesive film usually CANNOT be removed from displays without leaving residue after a few weeks or months of use.

Removable without residue

Von allen Untergründen kann das OnScreen ® Hybridglas problemlos und rückstandsfrei wieder entfernt werden.

. A strong 256-bit encryption secures the data transfer. With our externally issued SSL certificate, we are transparent and compliant. In addition to the SSL-secured website, we take data protection very seriously.

. A strong 256-bit encryption secures the data transfer. With our externally issued SSL certificate, we are transparent and compliant. In addition to the SSL-secured website, we take data protection very seriously.